Press release -

Invisible digital security seal from idem telematics protects swap bodies against burglars

- New telematics functionality developed by idem telematics and Emons

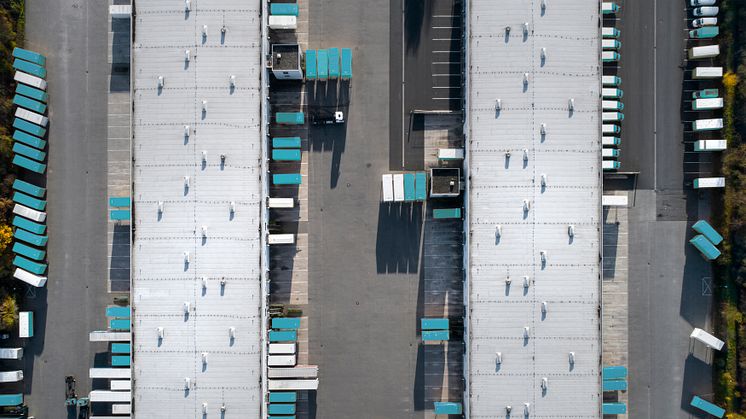

- Simplified management and localisation of parked swap bodies

- Concept offers additional cost benefits

Munich/Ulm, 14.03.2018 --- The market-leading telematics system for trucks and trailers from idem telematics with its cargofleet3 portal, has now been upgraded with a novel swap body management and security offering. Enhanced security is provided by an invisible digital seal, and the new system simplifies management of both swap body fleets and their depots.

The new swap body management system for cargofleet3 was developed by engineers working for the BPW subsidiary idem telematics together with transport experts employed by the forwarder Emons of Cologne. No new hardware components are required to implement the additional functionality. The maintenance-free telematics box TC Solar continues to take care of the discrete power supply, and data capture and transfer, and the data are presented as required by users in the online portal and on portable tablets and smartphones.

First swap body management system to cater for depots as well

Digitisation simplifies the management and localisation of parked swap bodies, but this new solution offers even more. It automatically assigns the individual bodies to the depots that are responsible for them. A shortfall in the pool is immediately signalled by the cargofleet3 portal. Thanks to these features, cargofleet3 not only delivers end-to-end transparency and efficiency, but also analyses and optimises the depots’ performance. For the first time, the data can also be made accessible to external maintenance service providers. Damage is recorded by a mobile app, and each subsequent stage in the repair process is posted in the portal.

Digital security seal – a new concept with additional cost benefits

The invisible digital security seal is being introduced by idem telematics to protect swap bodies against cargo theft and offer users additional cost benefits. Cargo theft ranks among the most urgent problems of the transport industry. According to joint estimates of several industry associations, undertaken together with the BGL, which is the trade association and lobby group of the German road haulage, logistics and waste disposal sector, cargoes are stolen from almost 26,000 trucks a year. Expressed statistically, this corresponds to a theft being committed every 20 minutes. The stolen goods alone are valued at 1.3 billion euros, and the crimes give rise to additional losses of 900 million euros because of penalties for late delivery, repair costs, as well as loss of turnover and production downtimes for the intended recipients.

Applying conventional security seals is not only a nuisance, however, but also costs time and therefore money. In addition, seals that are visible from the outside indicate to thieves that the body contains valuable goods. The new digital seal, in contrast, is completely invisible and can safeguard the body and its cargo according to individually determined parameters (e.g. geofencing). Any authorised attempt to interfere with the door is detected immediately and triggers a message – to the driver, the forwarder and, if desired, to other interested parties as well. The digital security seal also generates a seamless record of its responses in a data format that is recognised for legal purposes. Emons contributed to the development from a cost perspective as well, and concluded that its ease of use could cut costs.

The digital security seal and new swap body management system are available as components of cargofleet3 with immediate effect. Their functionalities can also be enabled for existing users and configured for their specific internal processes if required.

Related links

Topics

Categories

About idem telematics GmbH

idem telematics GmbH, which is headquartered in Munich and operates a local office in Ulm, is one of the leading providers of telematics solutions for trucks and trailers. By consolidating the data worlds of towing vehicle units and trailers, the telematics specialist – a member of the BPW Group since 2012 – can also offer an all-in-one system for the complete tractor-trailer. The telematics solutions from idem telematics GmbH increase the transparency and economic efficiency of transport processes for vehicle operators and in this way make a significant contribution to implementing the international mobility partnership of the BPW Group. idem telematics currently employs more than 70 people. www.idemtelematics.com

About BPW Group

BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.wethinktransport.com