Press release -

Because uptime is everything: At Agritechnica, BPW AGRAR to showcase solutions and services that keep farmers rolling

- BPW AGRAR engineers running gear for ultimate uptime – from design to 360° service

- Running gear leader strengthens unique bond with farmers and vehicle manufacturers

- Born digital: New QR code reveals all manuals, spare parts, and maintenance details

- BPW’s Active Reverse Control steering system makes vehicles more agile than ever

Szombathely, 6 October 2023 --- In agriculture, nature sets the timing: Seizing the right moment can often make or break the successful growth of plants, animals, and businesses. That is why BPW AGRAR is putting the uptime of agricultural vehicles and machinery at the heart of its Agritechnica presentation: At Booth D05 in Hall15, BPW will showcase intelligent, digitized running gear and all-round service concepts that keep the farmer up and running at all times.

Fascinating machines and vehicles will draw in trade visitors and the media at Agritechnica, the world's leading trade fair for agricultural technology (12 - 18 November). On many tractor-trailed vehicles showcased in in Hanover, Germany, a quick glance at its axle is enough to assess its quality: The logo of BPW AGRAR, farming specialist of the global innovation leader in running gear systems, graces the wheel hubs of the most innovative, robust, and sustainable vehicles on show.

At Agritechnica, BPW AGRAR is placing a passionate performance promise at the heart of its trade fair presentation: "Keep rolling", inspired by Rawhide, the popular country song by Frankie Laine, pledges ultimate uptime to farmers. A unique engineering approach ensures robustness and durability throughout the entire life cycle of construction, assembly, operation, maintenance, and spare parts service. For the first time, BPW AGRAR running gears reveal its digital DNA by simply scanning its unique QR code: Workshops and drivers just whip out their smartphones to easily access service-related product data, including parts lists or manuals. Service technicians see exploded part diagrams for their selected axle. From parts such as wheel bearings and nuts to kingpins and brake cams, including seals and suspension components, a complete parts analysis in seconds simplifies and enhances work precision.

BPW AGRAR now simplifies grueling maneuvering on narrow country lanes and in farmyards with the new Active Reverse Control electrohydraulic steering system. The system eliminates the need for complicated and bulky metal rods under the vehicle: a robust hydraulic system on the steering axle powers its turning. It can be conveniently installed by the vehicle manufacturer as a prefabricated module and controlled from the tractor. Additionally, the system shortens loading time and extends tire life.

András Virányi, Head of Product Management, Agricultural Solutions: “These underscore our engineering approach that addresses not only vehicle operation in the field, but also each and every single handling step during vehicle assembly, maintenance and parts management. The digital DNA of our running gear enables us to support highly customized vehicle concepts with a minimal variety of parts. With the Active Reverse Control, we show how we make trailed vehicles more agile, smart and nimble, without sacrificing simplicity and robustness. This also applies for a newly defined line-up of sensor technology.”

The profound relationship with farmers is also reflected in BPW's 30-ton AGRO Robust heavy-duty pendulum axle, showcased at Agritechnica. It enables farmers to transport enormous loads safely and steadily over even difficult off-road conditions. Where conventional axles would tip the vehicle, the independently suspended wheels on BPW’s pendulum axle gently follow any ground without crushing it. Designed for tremendous load capacity and maximum reliability, special low-maintenance, heavy-duty plain bearings are built to keep the farmers rolling – at all times.

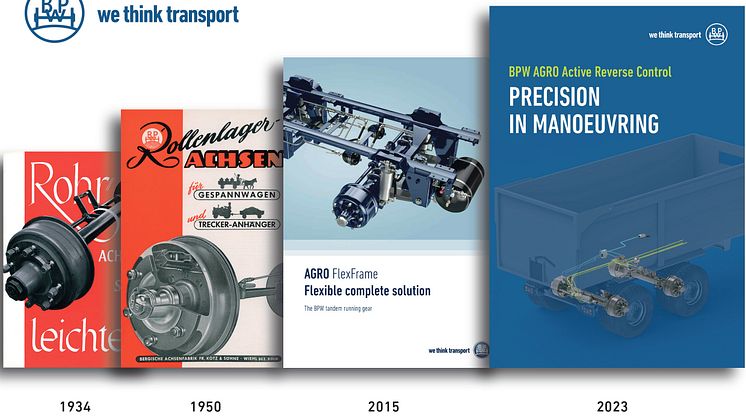

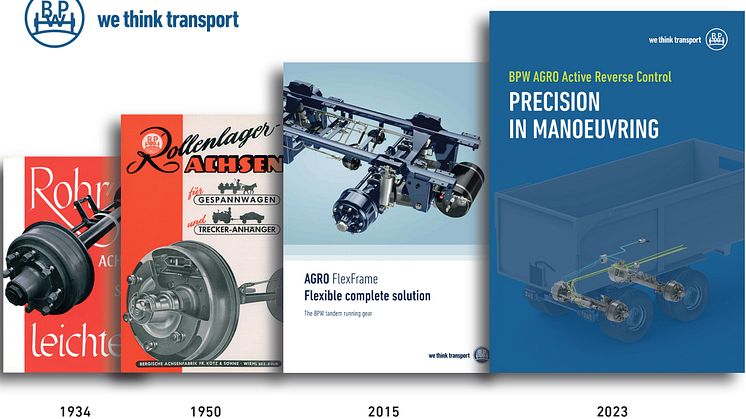

The way BPW develops, designs, builds and services running gear is based on a strong bond that is equally strong with vehicle manufacturers and vehicle users. It stems from the founding innovation of the family-owned company 125 years ago: Self-lubricating axles for horse-drawn carriages dramatically reduced maintenance and increased vehicle uptime and thus its sales potential. This principle has remained unchanged to this day. This is why the BPW trade fair stand at Agritechnica will become once again be the meeting place for the industry. Here, farmers, vehicle manufacturers, and BPW engineers will share ideas and experiences and strengthen their cooperation.

Péter Csánk, Global Business Development and Sales Director, Agricultural Solutions: “Only by genuinely knowing how farmers work, think and feel can you tailor technology and services to help them do any job, anytime. We see BPW as the passionate farmer's ally, keeping them up and running, always. That's why 1,500 employees at BPW AGRAR are exclusively committed to farmers and their vehicle manufacturers and have built up a service network across Europe that is second to none.”

Related links

Topics

Categories

About BPW Agrar

BPW-Hungária Kft. is a wholly owned subsidiary of BPW Bergische Achsen KG and specialises in agricultural running gear systems and specialist axles in the BPW Group. The company’s product portfolio ranges from moving axle stubs to single axles and complete tridem running gears with frames, including suspension and fitted brake systems for a unit load of over 30 tonnes. Over 1,500 employees produce the high-quality and technically sophisticated axles and running gear systems in Hungary. The agricultural products are sold through the member companies of the BPW Group around the globe. www.bpwagrar.com

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in 27 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en