Press release -

BPW revolutionises the running gear for trailers with modular architecture and "digital DNA"

- Lighter, more versatile, more efficient, more digital: BPW has completely redesigned the running gear for trailers

- Modular architecture provides manufacturers with flexible assembly options and the shortest processing times with minimum stock on hand

- Processes are digitalised right from the point of configuration and purchasing

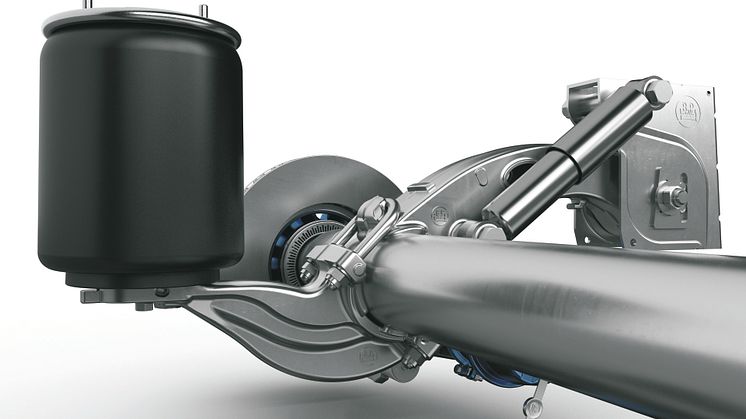

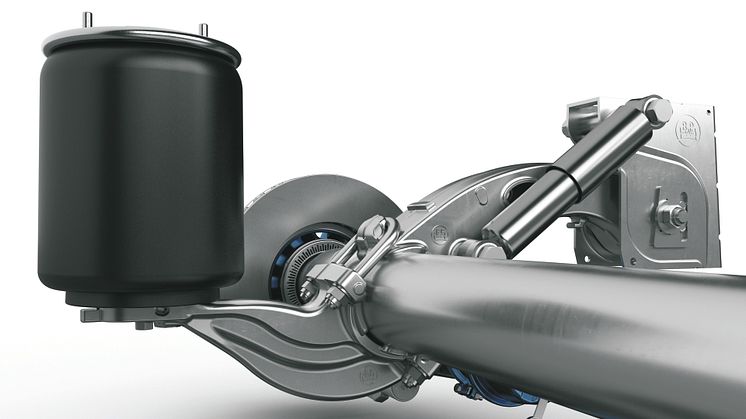

- For the first time, patented laser technology enables BPW's typical clamped modular air suspension system to be combined with round axle beams: saving up to 27 kilograms in weight

Wiehl, 04/09/2018 --- BPW, a leading supplier of axles and running gear technology for commercial vehicles worldwide, will be presenting a new platform for trailer running gears at the IAA: completely redesigned and digitalised, the configuration, construction and manufacturing of trailers has been considerably slimmed down and sped up. To do this, BPW use newly developed laser techniques; a "digital DNA" accompanies the running gear throughout its service life.

Foodstuffs, building rubble, medicines, TVs or chemicals: millions of different commodities and goods are transported in trailers – and all transported goods place individual demands on the running gear. For this reason, a running gear that leaves market leader BPW's production line is not like any other. At IAA Commercial Vehicles, the company will be presenting a completely redesigned modular architecture for trailer running gears, which makes configuration, construction, production and servicing more flexible, whilst making considerable weight savings. The new generation of running gears BPW ECO Air replaces BPW bestsellers ECO Air Compact and ECO Air Compact HD. It is already in use with pilot customers and will be going into large-scale production from 2019.

In the future, running gears for on-road and light off-road use will be based on a single platform. A modular architecture with standardised intelligent components enables vehicle manufacturers to buy BPW running gears as a construction kit and assemble the components themselves on-site in their desired configuration. Using the example of a medium-sized vehicle manufacturer, BPW has demonstrated that its average throughput times can be reduced from 10 days to up to 2 hours. In addition, decentralised assembly offers maximum flexibility because the manufacturer can realise a greater variety of individual chassis, even late in the production process. Component storage is confined to a minimum.

BPW has registered the patent of their own laser technique, which for the first time enables a clamped air suspension system to be integrated into a round axle beam, without having to equip the axle beam with an additional mould part: the laser creates a three-dimensional profile in the components, which allows them to reliably interlock and at the same still be able to be dismantled. The modular, clamped design of the BPW air suspension kit means that, in the case of repairs, only the faulty components need to be changed in line with demand. BPW has been successfully using laser technology for 2 years; it has been tried and tested on the 9-tonne running gear "ECO Air Compact HD", as well as in the most demanding off-road conditions.

Combined with the modular air suspension design, this technology offers maximum variability and also saves weight: the running gear is 5 kg lighter than its predecessors, in combination with the also refined BPW TS2 ECO Disc trailer brakes a weight saving of up to 9 kg is achieved, which amounts to 27 kg in the case of a tri-axle suspension.

BPW has digitally redesigned its new generation of running gears: each component is systematically provided with information on all technical specifications and combination options. This means that the running gear can be configured online in a very short time. The vehicle manufacturer can directly integrate a CAD model of the running gear into their CAD construction. The intelligent system prevents errors in the configuration and speeds up the entire design and construction process. From the configuration, an order can be triggered, which equips the running gear with a "digital DNA": this automatically manages the production and delivery by BPW and also accompanies the vehicle throughout its service life in the case of servicing and the replacement parts service. Alongside the relevant production data, all data relevant to servicing, such as spare parts lists or service manuals can be called up using the QR code.

'As the inventor of the patented axle, BPW has been setting benchmarks in the commercial vehicle industry for 120 years – now we have reinvented the running gear for the digital era,' says Carlo Lazzarini, Member of the Board of Management in the area of Sales, Trailer Equipment & Solutions at BPW. 'We link patented metallurgical processes with an extensive digitalisation of all processes throughout the service life of the running gear – it is, so to speak, "born digital". Thanks to the online configuration and modular architecture of the running gear, we can support the vehicle manufacturer in the optimisation of their processes and at the same time make production simpler. Vehicle manufacturers and operators benefit equally from digitalisation – with unchanged uncompromising reliability.'

Topics

Categories

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.bpw.de/e