Press release -

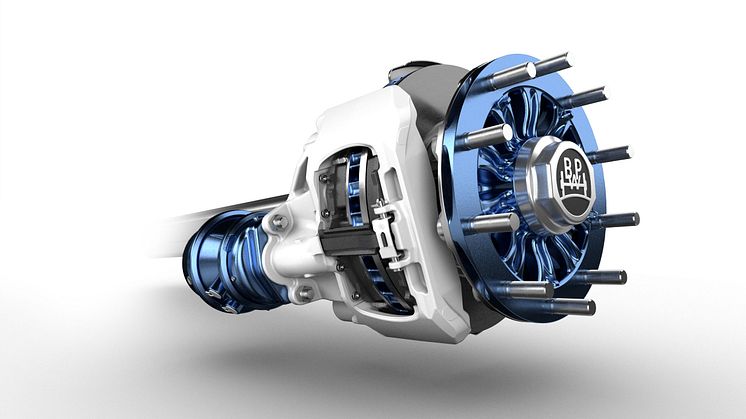

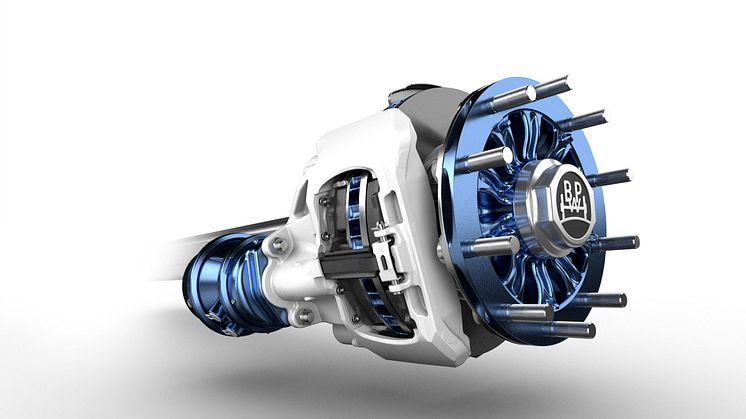

Even lighter, more robust and more economical: BPW will be presenting the new disc brake ECO Disc TS2 at IAA 2018

- Tried and tested disc brake now with modern single-tappet technology

- Special, unique offset tappet design to prevent skewed wear

- A reduced number of components saves weight and makes way for a more robust construction

Wiehl, 25/07/2018 --- Thanks to its intelligent design, the new disc brake ECO Disc TS2 sets new benchmarks in every way: it is now lighter, more robust and more economical. BPW will be presenting the innovative advances of its tried-and-tested product at IAA Commercial Vehicles 2018 (20-27 September in hall 26, stand C31) in Hannover.

The ECO Disc TS2 works with modern single-tappet technology and the specially developed, unique BPW Offset Tappet Design (OTD): thanks to a special configuration of the brake actuating unit with an offset tappet, an ideal balance of the forces and moments acting on the brake pad is achieved. The reinforced pad back plate also ensures even distribution of pressure between the pad and the disc. This ensures that the pads wear uniformly and so have a longer service life.

With this new design, the BPW engineers were able to reduce the number of components. In a multifunctional adjuster (MFA) the most important functions are logically integrated into a small number of innovative components. This means less interfaces and so fewer possible errors.

'As we have integrated the most important functions into a small number of innovative components, the number of interfaces is reduced even further, whilst the robustness of the overall system has increased,' explains Bernhard Rossenbach, Head of Product Management at BPW. In addition, the reduction in components makes the brakes lighter and more compact – in the case of a three-axle truck, a whole twelve kilograms of usable load is gained.

Another advantage is the usual user friendliness: the innovative compact design combined with BPW ECO Technology makes dismantling the brake caliper unnecessary when when changing discs – and, compared to conventional systems, saves up to three hours in the workshop per vehicle.

'The product has been perfectly thought out, very high-quality and durable,' says Carlos Lazzarini, member of the Board of Management, Sales Trailer Equipment & Solutions at BPW. 'These brakes ooze the know-how and experience of BPW, the biggest trailer brake manufacturer in Europe. As the only axle manufacturer producing its own disc brakes we know the overall system and are a competent contact person for our customers, who we can help quickly and directly.'

BPW Bergische Achsen KG's ECO Disc has been demonstrating its top quality in action out on the road for nine years. More than two million brakes have been produced in Hunsheim near the BPW headquarters in Wiehl: it is one of the most widely sold trailer disc brakes in the European market. With this reworking the new models TS2 3709 and TS2 4309 replace their predecessors: axles will be gradually converted to the new generation of trailer disc brakes from the start of 2019.

Topics

Categories

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About BPW Group

BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.wethinktransport.com