Press release -

idem telematics expands cargofleet 3 platform to include intelligent maintenance management

- Managing test intervals, maintenance schedules and vehicle fault messages is easy via cargofleet 3 portal

- Data can be entered manually or completely automatically via VIN number

- BPW has fully digitalised maintenance data for axle assembly units and running gears

- Jens Zeller: "Time- and cost-efficient relief for the fleet manager."

Munich/Ulm, 17/08/2022 --- Telematics is not only indispensable for heads of transport companies, drivers and dispatchers; access to vehicle data also provides a huge relief for fleet managers. Now, market leader idem telematics is expanding its cargofleet 3 platform to include intelligent maintenance management, which is already paving the way for AI-driven predictive and preventive maintenance.

Nothing in the world of transport is as costly as a vehicle that sits around in the garage, breaks down on the side of the road, collects fines due to poor maintenance, or, worst of all, causes an accident. Maintenance management is therefore one of the most important tasks that determines the cost efficiency of transport – it is also one of the most complicated: legal inspection regulations, manufacturers' maintenance schedules, or even status and fault messages coming from the vehicles themselves must always be kept under control, and maintenance must be skilfully scheduled and diligently documented. idem telematics has integrated all these tasks into cargofleet 3, its cloud-based portal for transport telematics: At the IAA Transportation trade fair in Hanover (from 20 - 25 September 2022, BPW Group stand in Hall 26/A30), the European market leader for trailer telematics is expanding its open-system platform to include intelligent maintenance management for trailers, vans, swap trailers and tractor units. The system keeps a maintenance calendar, sends reminders of upcoming appointments via email and records maintenance work in a digital vehicle file.

In addition to manual entry of inspection and maintenance information, idem telematics makes it possible to integrate the maintenance information provided digitally by the vehicle or component manufacturer into the portal via corresponding interfaces: The user only has to provide the VIN or the component number and then all the data is automatically entered into cargofleet 3 in a matter of seconds. The BPW Group is leading the way by providing all maintenance schedules for the 9t axle assembly unit programme and running gear components as early as the start of the service in autumn. Other leading manufacturers are also to follow shortly.

idem telematics has already designed the maintenance manager for the next wave of innovation in the commercial vehicle industry: In the future, it will not only be rigid maintenance dates or mileages that decide if and when vehicle components need to be serviced, but increasingly intelligent sensors too. The cargofleet 3 can already be used to check tyre pressure and the degree of wear of brake linings, among other things, with the system issuing a warning if necessary: This is a first step in the direction of predictive/preventive maintenance, which will also be used for other components and systems in the future.

Jens Zeller, CEO of idem telematics, states, "We're increasingly developing cargofleet 3 into the Swiss Army knife of transport telematics, with which all logistics and vehicle processes can be controlled more efficiently. The ability to organise maintenance matters digitally provides a huge relief for our fleet managers. At the same time, we now enable the vehicle and supplier industry to optimise their customer satisfaction and customer loyalty through digital service information. As the European market leader for trailer telematics, we offer manufacturers the market penetration and the reach it takes to successfully establish innovative service functions."

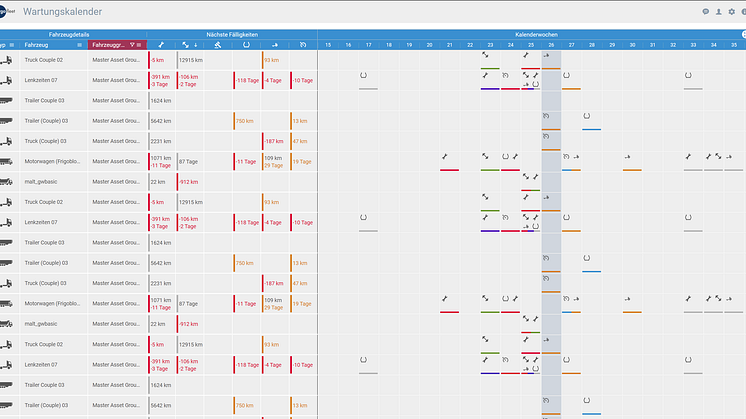

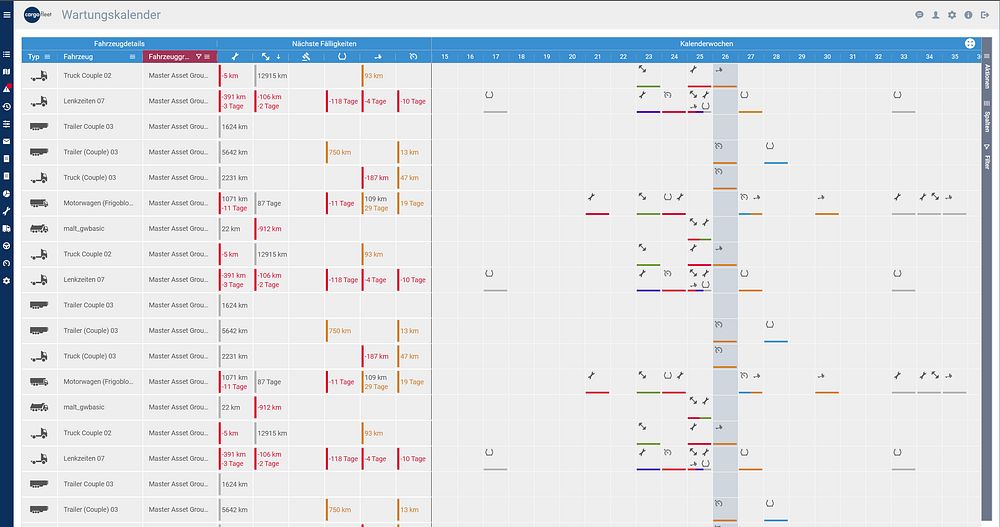

With the new digital maintenance management from idem telematics, you can keep track of maintenance intervals and inspection regulations for the entire fleet around the clock. (Source: idem telematics)

Related links

Topics

Categories

About idem telematics GmbH – Connecting all road transport

As Europe’s leading telematics partner, idem telematics supports forwarders, fleet operators and shippers in using data to continuously improve their core business, and thus to increase their profitability, customer satisfaction and competitiveness. Our systems are uncomplicated, independent, cross-fleet and cross-manufacturer, and adaptable to any company size and business model. The service: individual on-site process consulting – combined with the Europe-wide market-leading all-in-one cargofleet telematics platform for trucks, trailers, freight and logistics. Consolidating and summarising the data sets of vehicles, drivers and freight, idem telematics provides a complete system for increasing the transparency and economy of the entire logistics process. Benefits include unique customer proximity and flexibility for individual telematics requirements based on more than 20 years of telematics, transport and logistics expertise. idem telematics is a subsidiary of BPW Group and employs around 75 staff at its locations in Munich and Ulm. www.idemtelematics.com

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 6,800 staff in more than 50 countries and achieved consolidated sales of 1.372 billion euros in 2020. www.bpw.de/en