Press release -

BPW's aluminium hub achieves weight saving of 54 kilograms

- Load capacity raised by 18-kg saving per axle

- Greater load capacity reduces environmental burden

- Annual revenue increase of up to 540 euros

- First aluminium hubs already in service

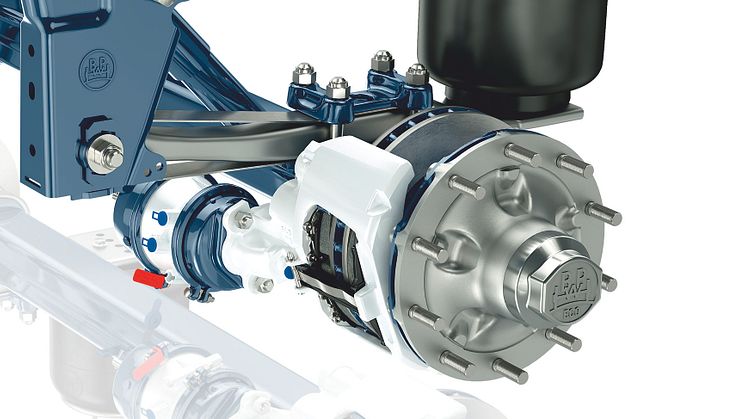

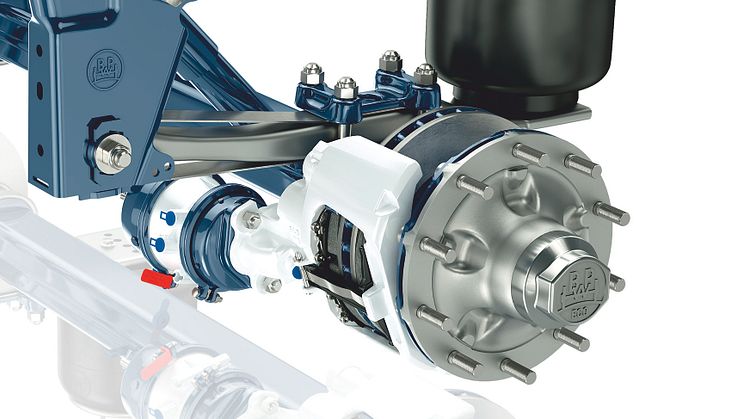

Wiehl, 09.05.2017 --- BPW Bergische Achsen KG has initiated series production of a forged aluminium hub targeted at lightweight semitrailers, and tankers and silo vehicles in particular. The hub can reduce axle weight by 18 kilograms and therefore curtail the weight of a three-axle unit by 54 kilograms. Customers in Germany and Sweden are already harvesting the benefits of this new solution.

For hauliers, weight economies translate into higher load capacity. A simple calculation illustrates the size of the gain: a weight reduction of 54 kilograms enables a heating oil tanker to carry an additional 64 litres. The extra load capacity enables the carrier to boost revenues by as much as 540 euros a year. The number of journeys is reduced by the vehicles' enhanced operating efficiency. Thanks to lower CO2 emissions, the environment benefits as well. When the vehicle is empty or carrying a part load, moreover, the lighter vehicle weight is reflected in decreased fuel consumption.

Cataphoretic dip-coating with zinc-phosphating gives the aluminium hub ideal protection against corrosion. These treatments also serve as a primer for top coats.

For air-sprung running gear equipped with the new aluminium hub, BPW grants its 5+3-year ECO Plus Warranty, which includes three years of cover for the brake cylinders, shock absorbers and air bags. The hubs can be retrofitted to existing axles on request.

The forged aluminium hub is initially available for nine-tonne axles with the BPW disc brake ECO Disc (TSB 3709 and TSB 4309), zero offset and the 335x10 wheel connection. It is combined with the BPW air suspension AirLight.

Topics

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About BPW Group

BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses more than 60 companies worldwide and employs around 6,400 people. www.wethinktransport.com