Press release -

AirSave: BPW automatically controls tyre and cost pressure

- BPW introducing a tyre pressure control system at the transport logistic trade fair – delivery to begin in November

- AirSave quickly pays for itself: savings of over 700 euros and 655 kilograms of CO2/year

- Proven technology, optimised and digitally integrated – connection to telematics system planned

Wiehl, 09 May 2019 --- The shreds of blown truck tyres are a typical sight along the edge of the motorway. Yet blown truck tyres are anything but harmless – tyre blowouts are highly dangerous and even minimal pressure losses can be extremely costly for hauliers. This is why BPW will soon be offering a tyre pressure control system ex works that pays for itself during the very first year.

Truck tyres have to withstand a great deal: load weights, road conditions and temperatures that are constantly changing can quickly lead to pressure differences that will rapidly wear out the tyres. The costs of premature wear alone are enormous. If a tyre blows out, it can have unforeseeable financial consequences due to downtime or even accidents.

According to a British study, 82 per cent of tyre blowouts can be effectively prevented if the tyre pressure is controlled automatically. This is why BPW will soon be offering a robust control system ex works that pays for itself in the first year: BPW’s new ‘AirSave’ system delivers a cost benefit of more than 700 euros per year for a three-axle vehicle with a mileage of 120,000 kilometres per year and an average pressure deviation of 10 per cent as a result of the fuel savings (around 250 litres) and the longer service life of the tyres. And this figure does not even include the time, nerves as well as vehicle and delivery interruptions saved. Thus a three-axle vehicle with the AirSave system protects the environment by saving 655 kilos in CO2emissions per year – and protects the side of the motorway from the remains of blown tyres. As a petroleum and chemical product, tyre scraps belong properly disposed of, not littering the environment.

For its system, BPW relies on a technology that has proven itself on the market and has been further optimised in many respects. As a mobility and system partner, BPW sets great store by an independent, particularly robust and easy-to-install design for all external components mounted on the wheel end. AirSave requires no maintenance for three years and always maintains the correct tyre pressure – even if the tyre is damaged, it improves its emergency running properties. The system uses the existing trailer pneumatics and, with a fully automatic booster pump, ensures that the preset tyre pressure is maintained at all times. The air is guided through the axle beam to the wheel end and from there to the tyre valve. The system displays a permanent loss of pressure. AirSave kicks in at a pressure deviation of just 0.2 bar – making it more reliable than other standard tyre pressure monitoring systems.

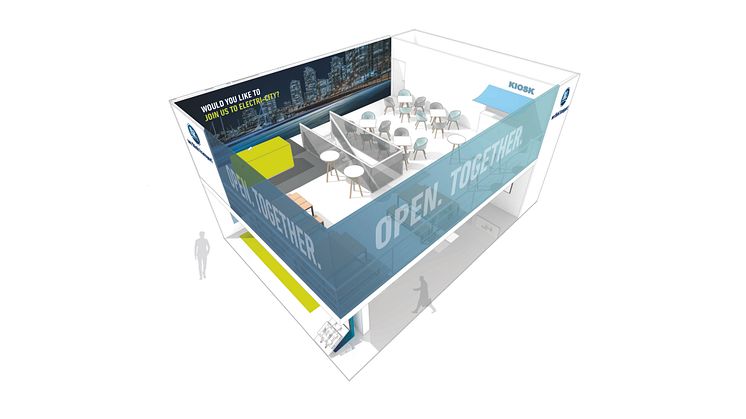

The ability to connect to the system digitally is a feature typical of BPW products: an optional connection to the ‘cargofleet3’ telematics portal from idem telematics is available, which then alerts the dispatcher in the event of pressure loss via the telematics portal. The driver also receives a warning via the cargofleet driver app. In future, AirSave will also be able to be selected at the click of a mouse when ordering running gear via the BPW online configurator. AirSave will be introduced at the transport logistic trade fair (from 4 to 7 June 2019) in Munich at the BPW Group’s booth 310 in Hall A6, and will be available for purchase starting in November 2019.

‘AirSave ensures that the vehicle is always operational and runs cost-effectively,’ says Bernhard Rossenbach, head of product management at BPW in Wiehl. ‘The fact that the system fully pays for itself within the very first year is an example of the BPW effect that massively benefits transport companies. At the same time, AirSave enhances safety and protects the environment and is therefore also eligible for de-minimis subsidies.’

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen Kommanditgesellschaft is the parent company of the BPW Group. With over 1,600 employees, including around 120 trainees, the family-owned company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also offers vehicle manufacturers and operators the ability to increase the efficiency of their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en