Press release -

Formula 1-style brake service: BPW also introduces ECO Plus 3 technology for axles with an axle load of 10 to 12 t

- BPW converts axles from 10 to 12 t axle load to ECO Plus 3 bearing technology

- Even better serviceability and easiest stocking of spare parts

- 5+3 years ECO Plus warranty offers eight years of security

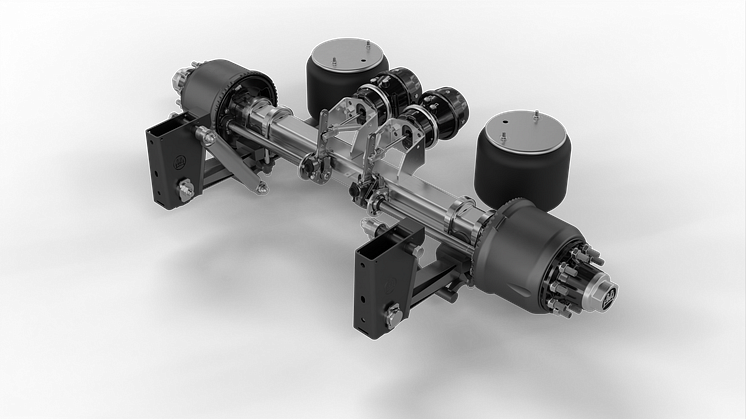

Wiehl, 1/9/2023 --- BPW is standardising its bearing technology and, after the 9 t axles, will also convert all units with axle loads of 10 to 12 t to ECO Plus 3 bearing technology. In addition to Formula 1-style wheel-end dismounting via the central torque-limited axle nut and the resultant ease of servicing, the latest generation of bearings offers many other advantages in the area of maintenance.

This means that irrespective of wheel size, brake type and other structural characteristics, all BPW products in these axle load classes enjoy the benefits of innovative ECO Plus 3 bearing technology, which has already proven its worth on countless occasions since its introduction in the 9 t axle segment in 2015.

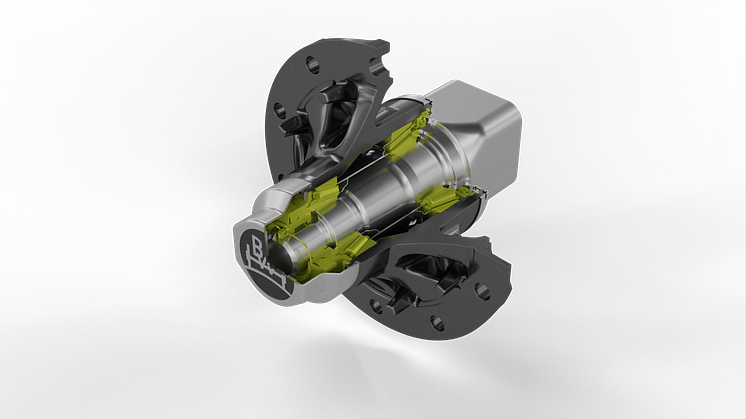

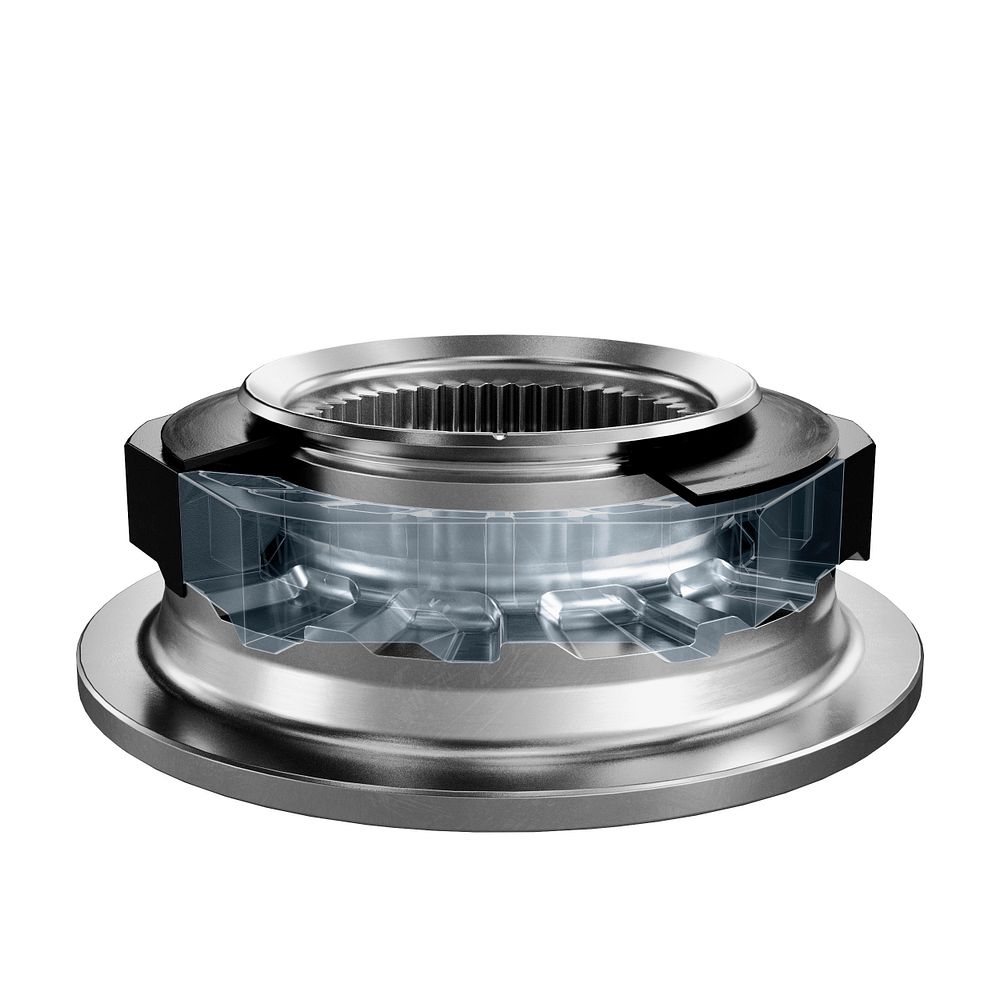

BPW has revolutionised the operation and maintenance of trailer axles with the invention of the ECO Plus bearing. As in Formula 1, the hub with the stepped bearing can be disassembled and assembled quickly via a central axle nut and without special tools such as pullers. If the wheel bolts are loosened beforehand, the brake disc can be "popped out" of the calliper with a flick of the wrist after pulling off the hub. With drum brakes, the complete wheel-hub unit can even be removed and all brake components such as brake shoes can be replaced directly.

The central bolt also has an integrated torque limiter, thanks to which the correct bearing play can be set automatically and without the use a torque wrench. The ECO Seal sealing system protects the maintenance-free, sealed bearing system from the ingress of dirt. In addition, BPW only uses DIN ISO tapered roller bearings on ECO Plus axles, which are readily available worldwide. BPW is thus setting standards with respect to ease of maintenance and service. Customers can carry out common maintenance activities in the shortest possible time, minimise downtimes and further increase availability of the trailer.

Compared to the previous versions, the third-generation bearing technology also offers fleet operators numerous other advantages, especially in terms of serviceability, operating costs and mileage. For example, the tightening torque of the hub cap is only 350 Nm instead of 800 Nm, which makes it easier to work on. In combination with the ECO Plus 3 seal, an O-ring under the capsule and the new, one-piece bearing spacer protect the bearing even more efficiently from the ingress of dirt during vehicle operation. In addition, the bearing spacer with the grease cartridge is now made entirely of plastic and can be replaced more easily if required. The exciter ring is now pressed onto the block and, in contrast to clip-on designs, can be reassembled without play after disassembly and re-used.

The large number of common parts between the individual axle types of the ECO Plus 3 generation simplifies spare parts stocking and parts identification for customers. In addition, when servicing and maintaining ECO Plus 3 axles, the same operations are always necessary with the same standard tools. This also contributes to even faster workflows.

The sealed design of the bearing system facilitates high running performance. So naturally BPW also guarantees high reliability for the latest generation and offers the 5+3 year ECO Plus warranty for all ECO Plus 3 units in the on-road and standard off-road range. This applies to the axle beam, hub, hub bearing, air suspension connection and air suspension hanger bracket. The warranty is extended by a further three years following the mandatory service check after five years. This offer applies across Europe and without mileage restrictions.

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in more than 50 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en