Press release -

From fields to construction sites: Award-winning "AGRO Drive" drive axle from BPW also available for construction trailers

- No stopping it: Hydraulic axle drive makes drawbar trailers suitable for off-road use

- 25% more traction in difficult terrain – robust hydraulics, simple maintenance

- Integrated freewheeling, homologated brakes and intelligent sensors

Wiehl, 12.03.2019 --- Soft, loose and wet ground and slopes quickly push even hauled construction vehicles to their limits. With a hydraulic drive axle from BPW, drawbar trailers are now digging their own way out of the sludge: originally developed for agricultural use, the award-winning "AGRO Drive" system is also taking construction sites by storm.

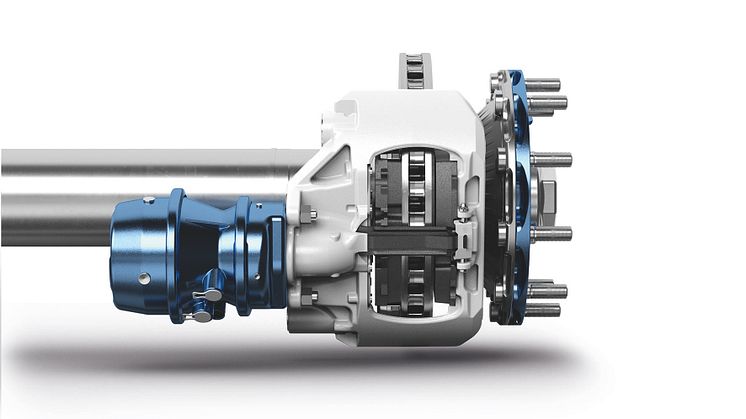

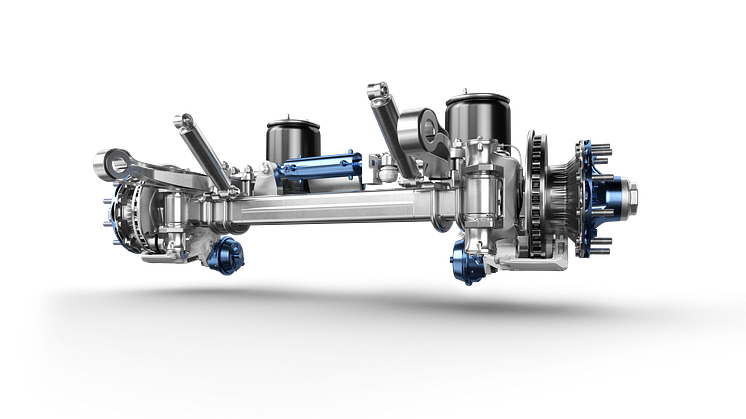

Whether tipper, mixer or tank, unpaved ground makes manoeuvring with any trailer type a real challenge – especially when it is wet, steep, sandy or muddy. Unless the drawbar trailer is able to get out of the mess all by itself, of course. The new "AGRO Drive" hydraulic drive axle from BPW makes it possible: a shiftable two-stage hydraulic drive with integrated freewheel moves heavy loads even under the most difficult conditions. Automatic freewheeling also enables use on roads and at higher speeds.

By distributing the drive power to two additional wheels, the system develops a high torque without damaging the ground. It is prepared for a tyre pressure control system (RDS) as standard, which optimises the contact area of the wheels for the particular ground conditions. With 25 percent more traction, smaller towing vehicles can handle higher axle loads of up to 13,500 kilograms at 40 kph. The installation position and cable routing of optional sensors (tyre pressure control system, rotation-direction and speed sensors, and ABS) has been designed to provide maximum protection and easy maintenance. Depending on the requirements, the system can be set up without suspension or can be combined with leaf, air and hydraulic suspension.

Another typical BPW benefit is the easy servicing of the brake system. The sophisticated design of the drive axle means that maintenance and brake lining replacements can be performed without removing the hydraulic drive motor, the brake drum is simply taken out.

Initially presented in October 2017 for agricultural use, the system advantages of the AGRO Drive quickly spread to the construction industry. At the beginning of January, the system was selected by the readers of the specialist media outlets ‘Agrarheute’, ‘Agrartechnik’ and ‘traction’ to receive the public choice award in Würzburg, Germany, for ‘Innovations in agricultural technology’ in the ‘Logistics’ category.

Peter Lindner, Agricultural Sales Manager for Germany and Benelux at BPW Bergische Achsen KG in Wiehl: "Going on when others stop – this adds a real competitive edge for building contractors, too. We are proud to officially present our new drive system for the construction sector for the first time at Bauma."

Bauma visitors will find these and other BPW Group solutions for the construction sector at Stand FN.827/9 in the open-air grounds of Messe München from 8 to 14 April.

BPW AGRO Drive in action

Topics

Categories

About BPW Agricultural

BPW-Hungária Kft. is a wholly owned subsidiary of BPW Bergische Achsen KG and specialises in agricultural running gear systems and specialist axles in the BPW Group. The company’s product portfolio ranges from moving axle stubs to single axles and complete tridem running gear with frames, including suspension and fitted brake systems for a unit load of over 30 tonnes. Over 1,500 employees produce the high-quality and technically sophisticated axles and running gear systems in Hungary. The agricultural products are sold through the member companies of the BPW Group around the globe. www.bpwagrar.com

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en