Press release -

BPW is now also making low loader trailers a dream to manoeuvre

- Electrohydraulic "Active Reverse Control (ARC)" auxiliary steering system available for low loader trailers for the first time – for fast and safe manoeuvring, even when things get tight

- Simple Plug & Play installation concept; can also be retrofitted

- Daniel Dautzenberg (Schwarzmüller): "Simple installation in only four hours"

Wiehl, 14.02.2019 – Large manoeuvring areas for deliveries are a luxury that construction site logistics specialists can only dream of. On inner-city construction sites, things are especially tight – and not only with regard to space, but also in terms of timing. Drawbar trailers can now manoeuvre faster and more safely with an innovative auxiliary steering system from BPW. The approval-free system can be installed in just a few hours – and is now available for low loader trailers, too.

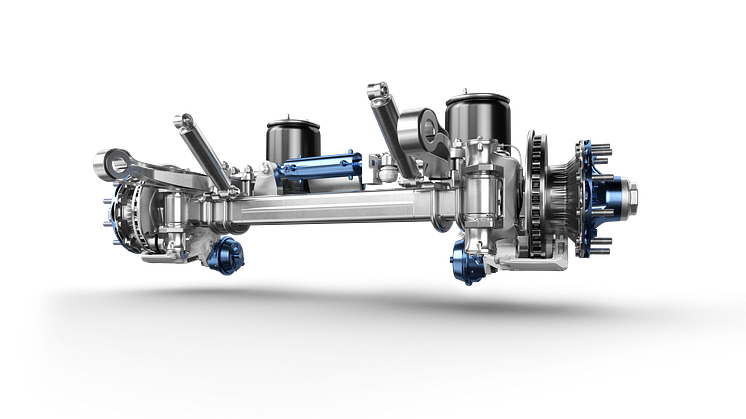

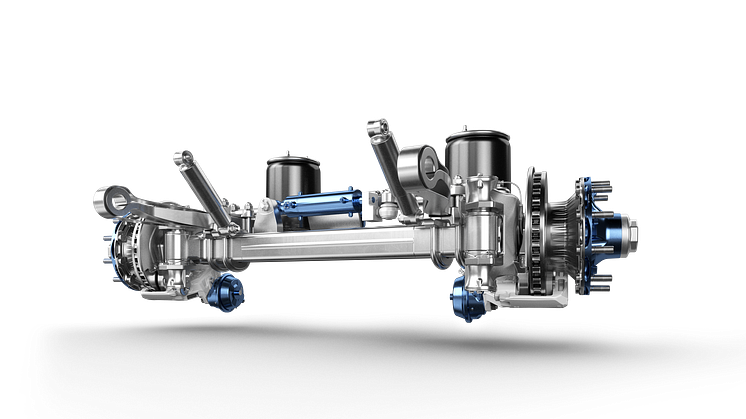

BPW is now extending the scope of application for its "Active Reverse Control" auxiliary steering system to low loader trailers as well: The compact system does not require separate approval, is straightforward to fit and even retrofit, depending on the chassis type. The auxiliary steering extends the BPW self-steering axle's function and application area. The design principle of the self-steering axle – which is also behind the manoeuvrability of office swivel chairs and shopping trolleys – gives the trailer a unique cornering ability and an amazingly tight turning circle, thus enabling fuel and tyre savings. Thanks to the auxiliary steering, all these advantages are now available when reversing and manoeuvring. The new reversing system is particularly interesting for contractors, because on many construction sites, the delivery and removal of material and machines is a matter of millimetres – and time.

The Active Reverse Control also saves time during installation: the system can be installed and calibrated in around four hours. According to Daniel Dautzenberg, Head of Design and Development at the vehicle manufacturer Schwarzmüller, where the first auxiliary steering system was commissioned in 2018, "BPW's Active Reverse Control is the first real Plug & Play system of the auxiliary steering systems on the market. Thanks to the axle being prepared and pre-assembled in the factory, installation and commissioning were quick and easy. After entering vehicle parameters, the system impressed us with its fast response time, both during the test drive and in operation."

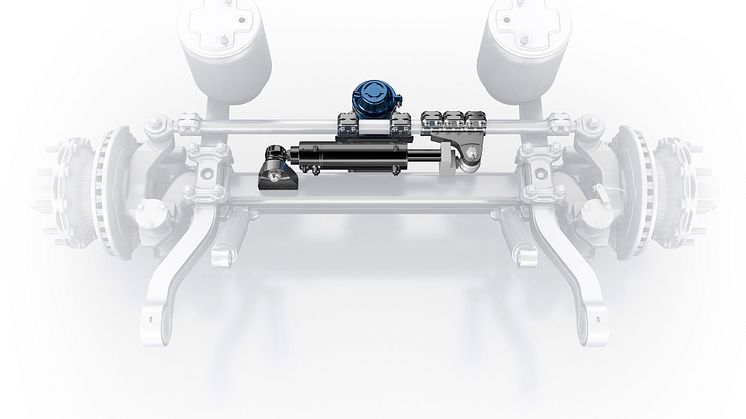

The system, which was awarded second place in the "Trailer Innovation Award 2019" category at the IAA Commercial Vehicles last autumn, consists of a control unit, a hydraulic unit and a steering cylinder with an integrated tracking sensor. The steering cylinder is fitted locally on the self-steering axle and is operated via the hydraulic unit with reservoir. The steering operates fully automatically: As soon as the driver engages reverse gear, it is activated via the reversing lights and the rotational speed and rotational direction sensor. The control unit uses innovative sensor technology that automatically detects the direction and angle of steering. The auxiliary steering system is only activated when reversing. When moving forwards, the system is passive and the steering is performed mechanically via the self-steering action.

BPW will be exhibiting the Active Reverse Control auxiliary steering system at Bauma in Munich from 8 to 14 April at Stand FN.827/9.

Video: electro-hydraulic auxiliary steering system Active Reverse Control

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen Kommanditgesellschaft is the parent company of the BPW Group. With over 1,600 employees, including around 120 trainees, the family-owned company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also offers vehicle manufacturers and operators the ability to increase the efficiency of their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en