Press release -

System configuration by smartphone: BPW ARC App for electrohydraulic auxiliary steering system Active Reverse Control

- BPW ARC App for vehicle operators, vehicle manufacturers and service stations

- Perform initial commissioning and function checks easily via smartphone

- System status, notifications and alarms at a glance

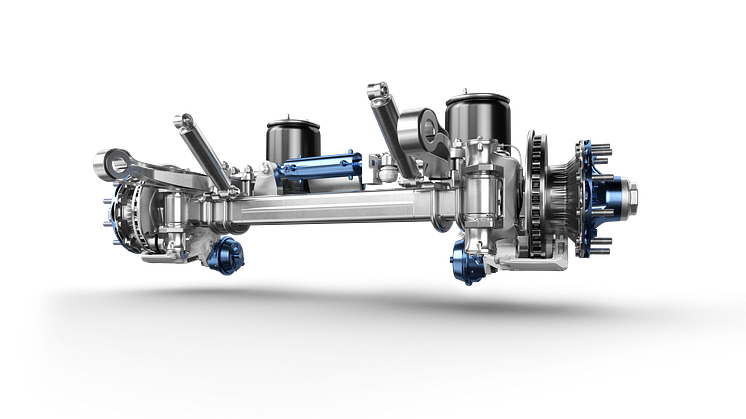

Wiehl, 7.6.2022 --- BPW's electrohydraulic auxiliary steering system Active Reverse Control (ARC) for Self-steering axles has already made it easier to reverse with truck drawbar trailers and semitrailers in tight manoeuvring spaces. Now BPW is also making initial commissioning, function checks and diagnostics of this system easier with the BPW ARC App, available to download for free for Android and IOS devices in the Play Store or Apple Store in English, German, French and Italian.

Diagnostics of wired system via laptop is a thing of the past: today, drivers, vehicle manufacturers and service stations simply need to whip out their smartphones to configure BPW's Active Reverse Control during initial commissioning, to access system information, perform system tests or query warning messages. BPW is the first provider to introduce an app for its electrohydraulic auxiliary steering system that gives users speedy access to all important information via a Bluetooth interface to the system control unit.

After downloading the app, users can register for a suitable user profile with BPW with the corresponding user rights. For example, with basic access, the driver has the option of calling up steering parameters, checking the power supply or viewing alarms. As a registered user, the driver can also adjust the steering sensitivity (reactivity) of the system to their own driving preferences from the standard settings by +/- 20%. The driving behaviour of the trailer when reversing changes depending on the reactivity settings. A higher degree of reactivity causes the axle to react earlier, meaning that the axle turns in more quickly with a greater angle at the beginning of the turn. Conversely, a lower degree of reactivity means that the steering axle turns into the curve to a lesser extent at the beginning of the curve but realigns itself more quickly during forward travel.

Vehicle manufacturers can use enhanced user functions as part of the commissioning of the electrohydraulic auxiliary steering system, for example to easily select the right configuration for their vehicle via the app, to set the maximum steering angle and bleed the steering axle as well as to perform system tests and view, edit and reset warning messages.

Ziya Albayrak, Product Manager at BPW: "With our auxiliary steering system Active Reverse Control, drivers can manoeuvre their trailers with self-steering axles faster and more safely, even when reversing. The reversing system is particularly interesting for those applications where space for manoeuvring is limited for loading and unloading, for example on narrow streets in city centres or on construction sites and depots. The new BPW ARC App now allows vehicle manufacturers and service stations to work efficiently, because all information is available in one app in a user-friendly layout.

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 6,800 staff in more than 50 countries and achieved consolidated sales of 1.372 billion euros in 2020. www.bpw.de/en