Press release -

BPW: Top engineering for low loader trailers

- High-tech chassis in the tightest of spaces makes low loader trailers more versatile, robust and agile than ever before

- Market leader BPW opens up new application options with running gear innovations

- Peter Lindner: “As a family-owned company, predestined for demanding challenges”

Wiehl 8/9/2022 --- Low loader trailers are used on the road and off-road, because no other vehicle type transports large, heavy and complex goods from A to B more efficiently. Thanks to innovative running gear technologies, low loader trailers are becoming increasingly versatile and even more manoeuvrable. At bauma (outdoor area north, stand 827/9), market leader BPW will be showing what is technically possible - and what optimises added value in transport.

The goods that are transported by low loader trailer today are becoming increasingly larger, heavier and more complex. From car drawbar trailers to construction cranes, from industrial modules to reinforced concrete bridge components, vehicle manufacturers are pushing the boundaries of what is technically feasible. The vehicle concepts in this class are as varied as the transport tasks - whether as a drawbar trailer or semi-trailer, whether telescopic or as a low bed low loader trailer. The limit is set by the load capacity and the maximum passage height of bridges, tunnels and subways - so the only way to get more out of the trailer is to make it even lower and lighter.

Sophisticated axle and running gear technologies from BPW ensure that the loading area of the low loader trailer can be lowered far below the driving level for loading and unloading, thereby almost reaching the road surface at just a few hand widths. Modern low loader trailers transport heavy construction equipment or concrete components weighing several tonnes safely and accident-free to the site of operation, even on difficult terrain. This feat is made possible by the axle design: BPW axles - rigid or steered - are combined with the lightweight Airlight II air suspension or a hydraulic suspension; stub axles, for example, manage without a continuous axle beam and require only minimal installation space; swing axles can swing up and down individually with a large stroke so that the vehicle can also cope with asymmetrical unevenness.

BPW offers swing axles with reliable, maintenance-friendly and space-optimised technology for heavy low-loader trailers, semi trailers, special vehicles and modular platforms.

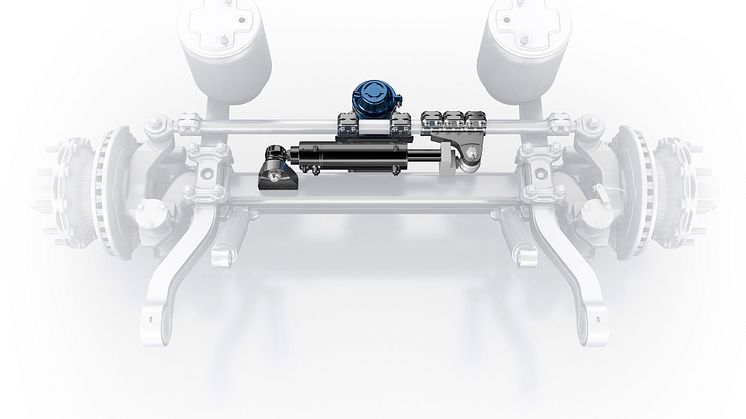

It’s no wonder that low loader trailers are regarded as top engineering: BPW Bergische Achsen KG has established itself worldwide as the preferred partner of low loader trailer manufacturers and, with innovative axles, brakes, suspension and steering technologies, enables heavy transport to become increasingly agile, powerful and efficient. BPW offers a uniquely wide range of running gear system solutions for low loader trailer vehicles with axle loads from 9 t to 14 t and 17.5" or 19.5" tyres. Self-steering axles from BPW give the low loader trailer unimagined manoeuvrability: with axle loads of 9 t to 12 t and steering angles of up to 27°, they manoeuvre even the heaviest loads to their destination with ease. A special feature is the load-dependent steering stabilisation: only by means of wave-shaped pressure discs and self-steering, the wheels are kept stable in the track depending on the load when driving straight ahead and are steered according to the bend radius when driving around bends.

The low loader trailer also becomes a smart mover when reversing thanks to an award-winning innovation from BPW: “Active Reverse Control” (ARC) is an electrohydraulic auxiliary steering system that controls the steering angle when reversing and when manoeuvring without a mechanical connection to the towing vehicle. For the first time, BPW is offering a smartphone app for Active Reverse Control, which enables the installation and set-up of the system, maintenance and also special additional functions in use: for example, the steering angle can be optimally adapted for special driving manoeuvres. “This example not only shows how innovations in mechatronics, digitalisation and running gear technology are intertwined at BPW,” explains Peter Lindner, Director Sales Customised Solutions at BPW, “it also illustrates what we mean by a system and mobility partnership. The vehicle manufacturer benefits from the significantly simplified installation of the auxiliary steering system according to the plug & play principle, the vehicle operator from the enhanced scope of use and functions as well as from once again simplified maintenance: the app is also available to garages and makes pit stops even more efficient.”

Reliability and ease of maintenance are the be-all and end-all for low loader trailers. A commercial vehicle that is in the garage does not earn any money - and a breakdown in special transports can have expensive consequences. BPW occupies a special position in the industry with the design of its components: axles, wheelends and air suspensions can be completely dismantled and serviced at record speed - because time is money. With the stepped bearing, the wheel hubs can be easily pulled off during maintenance; an innovative central bolt connection with integrated torque limitation ensures automatically adjusted play of the bearing. From 2023, this ECO Plus Wheelend generation will again make the maintenance and spare parts inventory of all 10-12 t axles drastically simpler. The sturdiness and durability of BPW components is legendary: low loader trailers, like many special vehicles, are often in use for 20 years or more. A KTLZn-coating of axle components provides for the maximum surface protection.

However, the most important success factor at BPW is the close cooperation with the vehicle industry. From axle types to brakes and suspension systems, BPW helps to achieve great individuality in the commercial vehicle industry. Under the motto “Challenge Us”, BPW engineers are always taking on new challenges to make low loader trailers even more versatile, powerful and economical. Peter Lindner: “As a family-owned company, we are not out to make a quick profit, but are looking at the long term and will continue to stand by our solutions for decades to come. In this way, we create a stable basis of trust to set ourselves ever higher goals together with the vehicle industry.”

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 6,800 staff in more than 50 countries and achieved consolidated sales of 1.372 billion euros in 2020. www.bpw.de/en