Press release -

Manoeuvre trailers with greater agility: BPW adds forward manoeuvring function to Active Reverse Control (ARC)

- Electro-hydraulic auxiliary steering now makes it easier to manoeuvre the trailer forwards and backwards

- Compact design, plug & play installation and app for easy commissioning and function testing

- BPW ARC available for a wide range of vehicle segments

With ARC, the compact, electro-hydraulic auxiliary steering system, BPW has been turning trailers into manoeuvring marvels since 2019. BPW is now adding a forward manoeuvring function to the award-winning solution. This means effortless and even faster manoeuvring with fewer steps – forwards as well as backwards.

Wiehl, 24 April 2024 --- Historic old towns, narrow access roads, overcrowded car parks, hectic construction sites and small idyllic farms all have one thing in common: they are a nightmare for truck drivers. Manoeuvring or reversing a trailer in the tightest of spaces can bring sweat to the brow of even experienced truckers. Even the smallest oversight can have expensive consequences. For this reason, the vehicle industry spent a long time struggling with the development of various steering systems for trailers. However, most of these have proved to be too complicated to operate, too complex to install and ultimately too expensive for trailers in most price categories and application scenarios.

With introduction of the Active Reverse Control (ARC) auxiliary steering system in 2019, BPW convinced vehicle manufacturers, transport companies and drivers right from the start: based on the proven BPW self-steering axle, an innovative gyroscopic sensor and software, ARC controls the self-steering axle electro-hydraulically when manoeuvring forwards and backwards. ARC simplifies even hair-raising manoeuvring tasks, reduces the risk of accidents and allows even less experienced drivers to complete demanding transport tasks effortlessly, quickly and safely.

When reversing, sensors as well as electrical and hydraulic systems ensure that the wheels are turned at the optimum steering angle. During forwards manoeuvring, the wheels previously followed the natural path of the self-steering axle and often did not have the required steering angle. With the new ARC generation, the wheels can also be actively steered forwards for the first time: the driver can use radio control to determine the steering angle of the trailer when moving forwards and backwards. This reduces the required number of manoeuvring operations even in the tightest of spaces, thus saving time, stress, tyre wear and reducing collision damage.

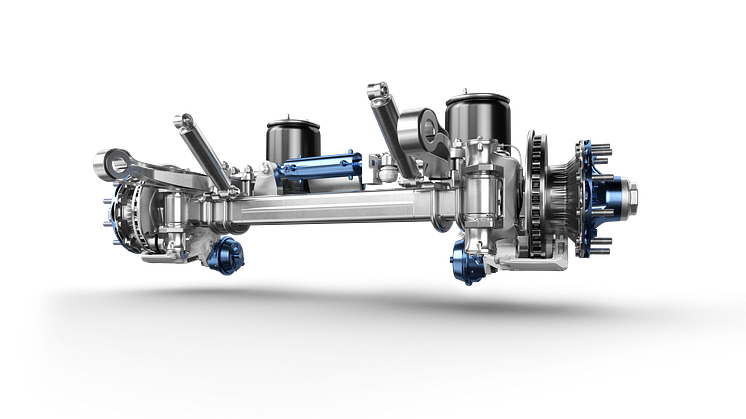

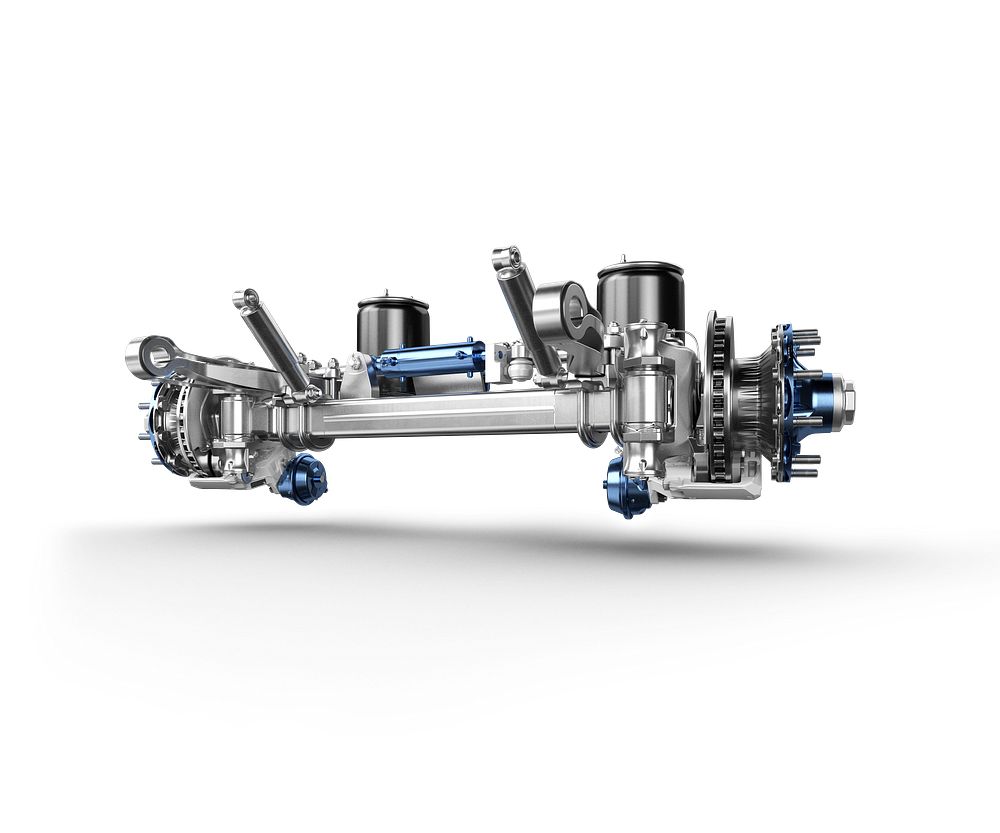

In each case, BPW ARC consists of a compact control and hydraulic unit as well as factory-fitted sensors and steering cylinders on the axle. The cylinder sits directly on the self-steering axle and is operated via the hydraulic unit with its supply tank. This keeps the underbody free of cumbersome linkages. Sensors on the kingpins are also not required. Control and hydraulic unit can be freely positioned by the manufacturer. Power is supplied either from the towing vehicle or independently from the battery. This flexibility allows vehicle manufacturers around the world to equip a wide variety of trailer types with ARC – including low-loaders, where the installation space is down to a matter of millimetres. The system covers a wide range of BPW self-steering axles with drum and disc brakes and is also approved for the transport of hazardous goods.

The new function makes ARC even more agile, but not more complicated: the forwards function is activated by the EBS system. BPW uses the ISS (Integrated Speed Switch) interface of the EBS system to implement the new function. BPW supplies an EBS connection cable harness ex works for easy connection. The axle prepared and pre-assembled with ARC at the factory by BPW allows the manufacturer to perform quick and uncomplicated assembly. The software is also pre-installed. As a further industry-wide innovation, BPW offers a free smartphone app that allows effortless initial commissioning, functional testing and remote diagnostics.

Ziya Albayrak, Product Manager at BPW: "With active forwards steering, we allow truck drivers and vehicle owners to cope with everyday transport tasks in a much more agile and straightforward manner. For vehicle manufacturers, the uncomplicated installation and commissioning of ARC is a distinct advantage in terms of flexibility and cost-effectiveness. They can offer auxiliary steering for a wide range of vehicle and price segments."

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in 27 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en