Press release -

Safer loading, more flexible manoeuvres: BPW receives two ‘Trailer Innovation 2019’ awards

- The most important industry prize from the 16 international leaders of the trade press and the VDA

- ‘Active Reverse Control’ makes the trailer a dream to manoeuvre

- BPW innovations make a significant contribution to safety and cost reduction

Wiehl, 27.09.2018 --- BPW can once again celebrate its win of an important innovation prize – twice over. A jury of 16 international trade journalists and experts from the German Association of the Automotive Industry (VDA) selected two innovations from BPW for the ‘Trailer Innovation 2019’ award. Both innovations combine a significant gain in safety with substantial cost savings for vehicle operators.

‘Innovation is when you can hear our customers’ tills ringing,’ says Dr Markus Kliffken, summing up the highest objective for BPW development. As a member of the management board, he is responsible for innovation management at BPW and had the honour of collecting two ‘Trailer Innovation 2019’ trophies for second place at the IAA Commercial Vehicles fair in Hanover. The ‘iGurt’ intelligent cargo restraint system and the ‘Active Reverse Control’ electro-hydraulic auxiliary steering not only reduce the operating costs for the vehicle, but also target the most common causes of accidents, which cause vast sums of damage each year: incorrectly secured loads and manoeuvring errors.

Video: iGurt digital cargo restraint system

The ‘iGurt’ from BPW is a handy sensor that is threaded onto the lashing straps in next to no time. It measures the preload and displays this on the housing, on the driver’s smartphone and in the telematics portal. This means that the cargo restraints can be monitored at all times to ensure that they are correct and this can be documented seamlessly. Damage caused by excessive tension can also be reliably avoided. This provides a great gain in safety: inadequate securing of loads causes around 20 to 25 per cent of road accidents in heavy-duty transport. Regulatory bodies find fault with more than 70 percent of inspected vehicles due to insufficient securing of loads. High penalties with costly and time-consuming re-securing and reloading work are the result, as well as high insurance costs. The ‘iGurt’ results in lower staffing costs for dealing with accidents and it reduces insurance costs significantly.

Video: Active Reverse Control

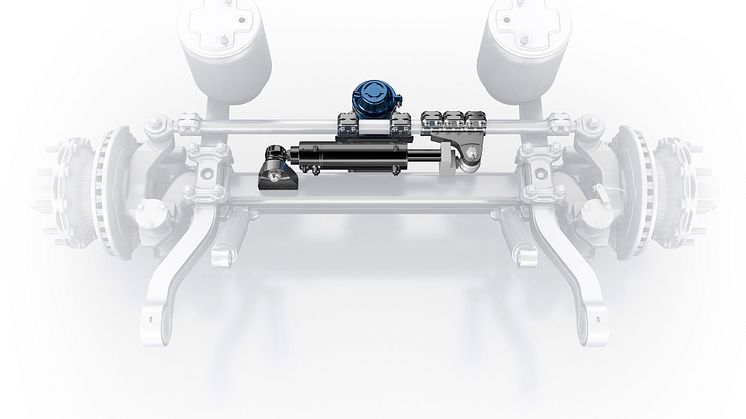

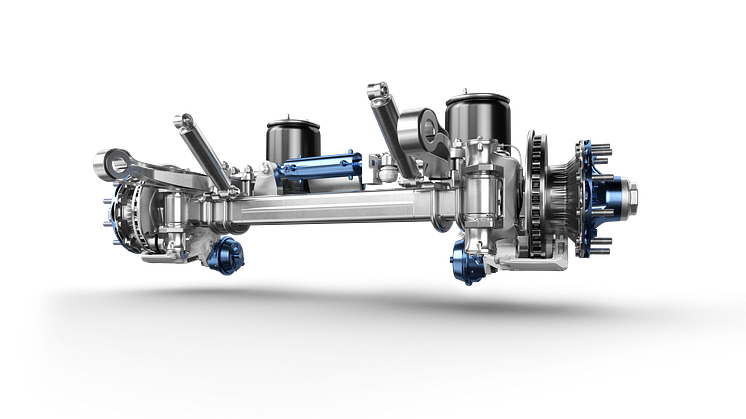

The ‘Active Reverse Control’ electro-hydraulic auxiliary steering system makes the trailer a dream to manoeuvre. The compact system does not require separate approval, is straightforward to fit and even retrofit – and is therefore so cost-effective that the outstanding manoeuvrability could potentially set a new standard for trailers. The auxiliary steering system is a clever enhancement of a true BPW bestseller – the self-steering axle. Its design principle – which is also behind the manoeuvrability of office swivel chairs and shopping trolleys – gives the trailer a unique cornering ability and an amazingly tight turning circle, thus enabling massive savings for fuel and tyres.

A compact hydraulics and control unit and the intelligent sensors mean that, for the first time, the trailer now also offers this manoeuvrability during reverse travel. The sensors use the reversing light to determine whether reverse gear has been engaged; the steering angle is set fully automatically and can also be controlled separately using remote operation if desired.

Dr Markus Kliffken says: ‘The iGurt and the electro-hydraulic auxiliary steering are innovations that target the key cost drivers in the transport business and that will quickly pay off for vehicle operators. We are thrilled to receive this award as it helps us to raise awareness of our developments among a broad and international customer base.’

BPW is presenting the iGurt and Active Reverse Control at the IAA Commercial Vehicles (20 – 27 September in Hanover) in Hall 26, Stand C31.

Topics

Categories

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.bpw.de/e