Press release -

HESTAL's green stroke of genius: FlowMaster reduces CO2-emissions and fuel consumption of the trailer – without additional effort and cost

- CO2 saving of up to 1.4%: strong contribution towards VECTO certification

- Fuel saving of 0.4 litres per 100 km: minimum effort, maximum efficiency

- Savings of over 860 euros in fuel costs at 120,000 km mileage/year

- Trade fair promotion: exclusive introductory offer for IAA TRANSPORTATION.

With aerodynamic fine-tuning, the product developers at HESTAL have been able to significantly reduce the aerodynamic drag of trailers – without significant additional costs for vehicle manufacturers and haulage companies. The HESTAL FlowMaster is even retrofittable and achieves savings that were previously only possible with complex and expensive new trailer designs. At IAA TRANSPORTATION, HESTAL is tempting visitors with a special trade fair promotion.

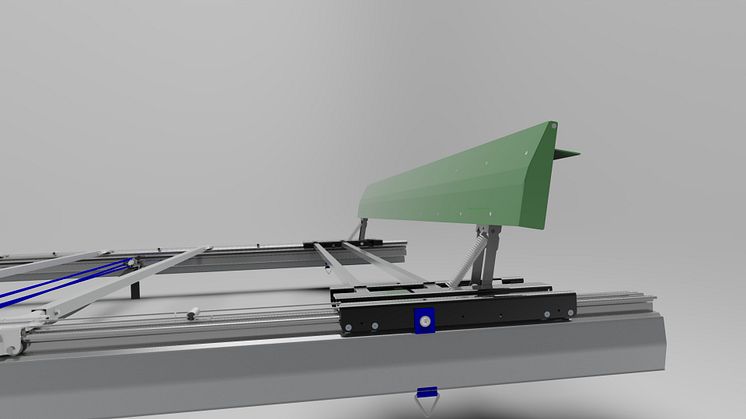

Dortmund, 27 August 2024 --- F. Hesterberg & Söhne GmbH & Co. KG, a subsidiary of BPW Bergische Achsen KG and known under the HESTAL brand, is presenting a surprisingly uncomplicated solution for improving the aerodynamics of trailers at the BPW Group stand at IAA TRANSPORTATION (Hall 26, Stand A30): the HESTAL FlowMaster. This aerodynamically optimised end beam promises to significantly increase efficiency in commercial vehicle traffic. The FlowMaster, a folding end element of the trailer roof to the rear frame, acts as an integrated roof spoiler: with a protrusion of just 55 mm beyond the end of the vehicle, it shifts the air turbulence far behind the semitrailer and thus reduces air resistance. This reduces the load on the tractor unit, as trucks use 30 to 60 per cent of their energy on long journeys simply to overcome aerodynamic resistance. A practical side-effect: the rear frame becomes less dirty. A patent has been filed for the solution.

The FlowMaster offers decisive advantages for trailer manufacturers: It makes a significant contribution towards VECTO certification with a CO2 saving of up to 1.4% without requiring significant design changes to the vehicle or the assembly process. It can be adapted to various roof types from almost all manufacturers. Transport companies also benefit greatly: in addition to the significant contribution towards VECTO certification, the FlowMaster allows fuel savings of 0.4 litres per 100 km. With an annual mileage of 120,000 km, a three-axle vehicle with HESTAL FlowMaster will save around 480 litres of diesel and 1.3 t CO2 – thus around 800 euros per year in fuel costs.

The strikingly green powder-coated end beam signals climate friendliness and economy even from a distance: the HESTAL product developers have managed to achieve almost the same increase in efficiency with aerodynamic fine-tuning as they have with creating futuristic-looking trailer concepts. In contrast to often cost-intensive new designs, which may use up load space, the FlowMaster is priced at the level of conventional end beams and can be easily retrofitted – either in the haulier's workshop or at any BPW service partner.

Dirk Miesen, Managing Director of F. Hesterberg & Söhne: "Genuine engineering doesn't always mean completely reinventing the trailer. It is often the subtle but well-thought-out details that make the big difference. HESTAL is already conducting intensive research into further innovations that, like the FlowMaster, are not visions of the future but that work in everyday transport reality."

For IAA TRANSPORTATION, HESTAL is offering the FlowMaster free of charge with every CoverMaster HESTAL sliding roof sold during the trade fair.

Related links

Topics

Categories

About F. Hesterberg & Söhne GmbH

The company F. Hesterberg & Söhne GmbH & Co. KG, based in Dortmund, is a reliable mobility and system partner for trailer superstructure technology. Under the brand name HESTAL, the company, which is certified to DIN EN 9001, offers innovative solutions from one source. The portfolio includes superstructure components for the truck and trailer industry. The technologies from Hesterberg & Söhne GmbH & Co. KG create maximum efficiency in loading and transport processes. www.hestal.de

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in 27 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en