Press release -

Out with the diesel engine and in with the electric axle – market leader in special-purpose truck construction initiates standard electrification programme for municipal utility vehicles with BPW axle drive

- One of Europe’s foremost special-purpose vehicle makers, the Paul Group, is converting the principal commercial heavy van operated by municipal utilities, the police and businesses to run on electricity

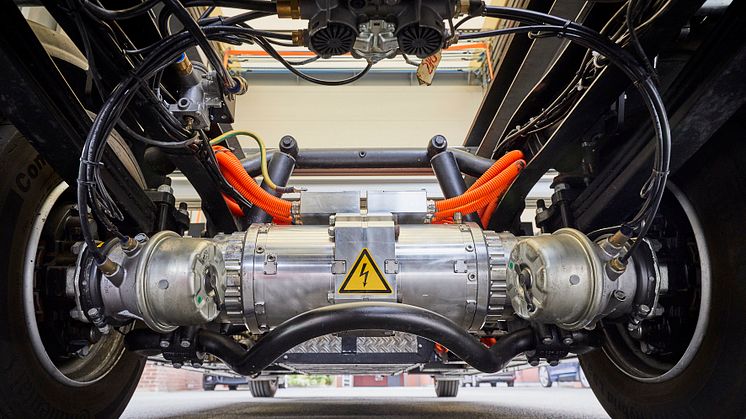

- BPW’s e-drive replaces the engine, transmission and emission control system without adding any weight

- Electric conversion gives custom vehicles new lease of life with zero emissions

Vilshofen/Wiehl, 30.01.2018 --- The electrification of municipal and commercial utility vehicles is now gathering pace following today’s announcement by the Paul Group, a European leader in special-purpose vehicle construction, of a standard conversion package for the Mercedes-Benz Vario in collaboration with BPW Bergische Achsen KG. The company revealed its plans at a preview for local authorities in Vilshofen in Bavaria.

The ingenious operation entails the complete removal of the conventional powertrain, consisting of the engine, transmission, differential etc.. Propulsion is provided by a new type of electric axle supplied by the transport and running gear specialist BPW. The conversion does not give rise to a heavier vehicle because the elimination of the engine, transmission and emission control system compensates for the additional battery weight. In fact, electrification actually makes the vehicle more agile. Torque substantially increases, for example, and the wheels can be activated individually. In addition, active steering control for the rear axle reduces the turning circle.

In view of its ruggedness and technical attributes, even after the official end of its production run the MB Vario remains one of the most popular platforms for the utility and special-purpose vehicles operated by local authorities, the police and armed forces, as well as numerous commercial enterprises. Its high payload, uncompromising reliability and large cab predestine the van for a variety of conversions. Special-purpose vehicles regularly have long service lives because they are operated only seasonally, and an electric successor to the MB Vario from the Mercedes stable is not currently in sight. Giving consideration to their operating profiles, moreover, municipal utility vehicles are ideal candidates for electrification. Many of them cover less than 100 km a day and are loaded at the same depot every evening.

Walter Pötzinger (1st from left), managing director of Paul Nutzfahrzeuge GmbH, comments, “Many authorities could ultimately be compelled to issue driving bans contrary to their own interests, given that they rank among the largest operators of diesel-powered commercial vehicle fleets. Electrification can allow their vehicles to remain in service for a much longer period. It is an economically viable option, especially since the e-drive costs less to operate and maintain than an internal combustion engine.”

Markus Schell (3rd from left), personally liable managing partner of BPW, remarks, “The standard conversion programme initiated by Paul sends an important message that has been eagerly awaited by fleet operators in the municipal, public agency and business sectors. But it also represents a crucial milestone on the road towards electric transport in general. We are delighted to have this opportunity to build on our long-standing mobility and system partnership with the company in the electric vehicle segment as well.”

Related links

Topics

Categories

About Paul Nutzfahrzeuge GmbH

Headquartered in Vilshofen an der Donau in Lower Bavaria, Paul Nutzfahrzeuge GmbH ranks among the European leaders in special-purpose vehicle construction. In recent years this division of the Paul Group has emerged as an accomplished global player serving customers the world over. Every year its running gear experts carry out chassis conversions, axle modifications, frame extensions, and special configurations on as many as 1,000 commercial vehicles. Paul Nutzfahrzeuge GmbH currently employs around 150 people.

About BPW Bergische Achsen KG

BPW Bergische Achsen KG is the parent company of the BPW Group. With more than 1,600 employees, including around 120 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About BPW Group

BPW Group, based in Wiehl, Germany, is a dependable international mobility and system partner for the transport industry, serving as a one-stop shop for innovative solutions. Its portfolio embraces axles, suspension systems and brake technologies (BPW), locking systems and bodywork technology (Hestal), lighting systems (Ermax), composite technologies (HBN-Teknik), and user-friendly telematics applications for trucks and trailers (idem telematics). BPW Group’s technologies and services support manufacturers’ cost-effective workflows and enable vehicle operators to manage their fleets efficiently by maximising the transparency of loading and transport processes. The owner-managed BPW Group encompasses 70 companies worldwide and employs around 7,000 people. www.wethinktransport.com