Press release -

This is how trailers are now using artificial intelligence to reduce operating costs

- New BPW running gear generation iC Plus analyses brake pads and performance

- Data patterns reveal braking problems before they become expensive and dangerous

- Technology that has been tried and tested in the UK for years now adapted for the rest of Europe

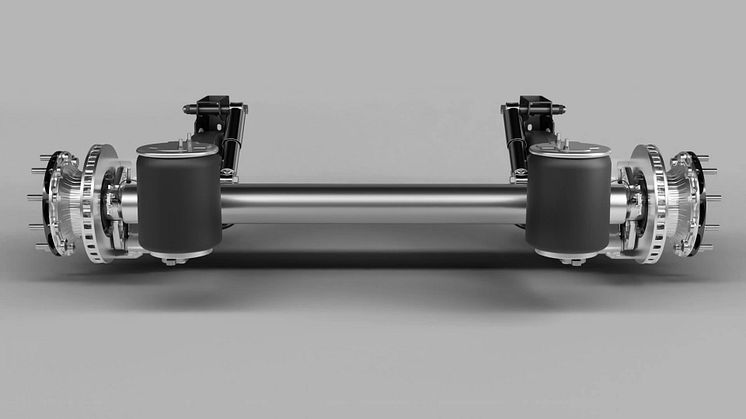

The AI revolution in transport is unstoppable: the trailer now recognises its optimum load based on the axle loading, checks critical components - and issues a warning before things get expensive and dangerous. The new iC Plus running gear generation from BPW uses intelligent algorithms to analyse braking performance. Something that has been saving testing and downtime in the UK for years is now rolling out across Europe for the first time.

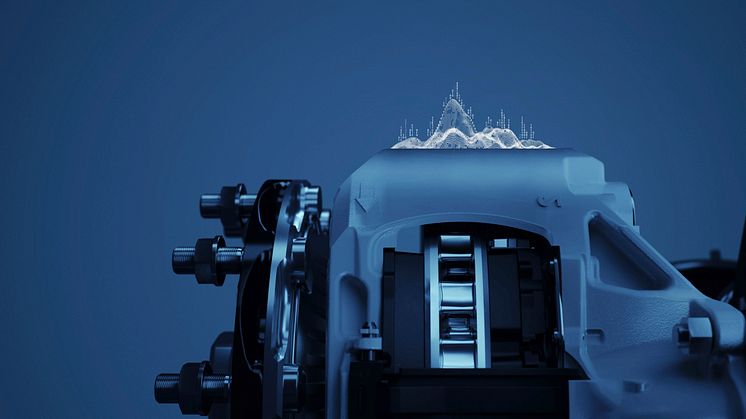

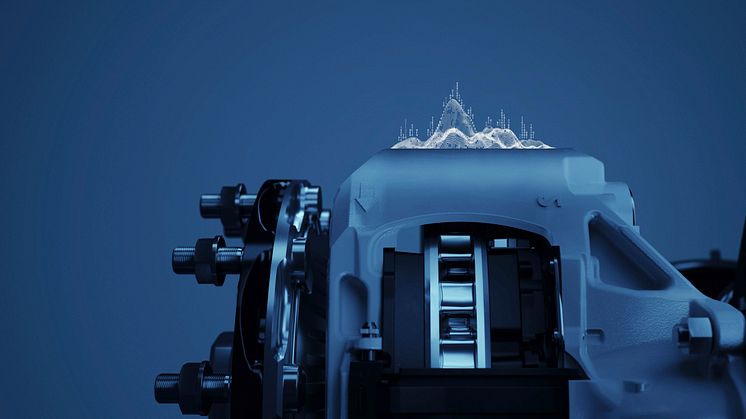

Wiehl, 6 June 2024 --- For years, the BPW Group has been driving forward digital networking of drivers, freight and vehicles so that transport companies can achieve greater efficiency with their trailer fleets every day: at BPW, trailer running gear has long been created as a digital twin; digital DNA opens up efficiency gains along the entire life cycle – from design and assembly to driving operations, maintenance and repair. But that was just the beginning. With the new iC Plus running gear generation, which comes with telematics hardware as standard, BPW is now creating the basis for the introduction of artificial intelligence into the trailer: intelligent algorithms detect data patterns in the running gear that e.g. indicate the need for maintenance of critical components. Above all, this includes the brakes: iC Plus informs the driver, fleet manager and dispatcher when the brakes need to be checked in the workshop. Causes can include a defective air hose, a sluggish brake calliper or a weakening spring on the cylinder – typical maintenance and repair tasks are recognised by artificial intelligence before expensive breakdowns or even accidents can occur. The highlight: BPW does not need separate sensors to analyse the braking performance, but instead accesses the data collected in the EBS. In addition to the brake lining wear sensors, the AI interprets the need for maintenance and repair in a differentiated manner in context. Temporary reaction patterns – triggered by a severe pothole, for example – are filtered out.

Brake performance measurement has already proven its worth in the UK, where close-meshed brake checks for trailers are required by law. For years, here, AI has been saving fleet operators expensive downtimes on the brake test stand. With the iC Plus running gear generation, BPW is also adapting its innovation for the rest of Europe.

Brake lining wear measurement is also tried and tested with iC Plus. It works with a sensor whose signals give the fleet manager sufficient flexibility to plan a workshop visit to change the brake lining. The BPW Group's digital services are also proving their worth here: the digital maintenance management system from BPW and idem telematics integrates statutory inspection regulations, maintenance instructions for BPW axles and vehicle status and fault messages. It also documents maintenance work down to the last detail – creating a digital vehicle file without any paper, hole punches or folders.

Caren Freudenberg, Product Manager at BPW: "Together with idem telematics, BPW has created a new generation of running gear that makes both vehicle operation and the entire transport process more economical. Rolling data analysis saves the fleet operator unnecessary visits to the workshop and maximises vehicle availability. All information relating to utilisation, operation, driver and vehicle performance is available to the fleet operator at any time at the click of a mouse via the cargofleet 3 telematics portal from idem telematics. This reveals potential and increases the efficiency of fleet management. The open-system platform also enables controlled, secure data exchange with external applications, such as transport management or ERP systems. Transport today couldn't be smarter or more efficient."

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs around 7,000 staff in 27 countries and achieved consolidated sales of 1.731 billion euros in 2022. www.bpw.de/en