Press release -

Always saving fuel, tyres, time and CO2: BPW now delivers the intelligent AirSave tyre pressure control system

- Successful practical tests: forwarders confirm solid cost advantages

-

Alfred Weyres, Alfred Weyres Spedition GmbH: "The purchase already pays for

itself in the first year"

-

Proven technology optimised and networked: AirSave sends tyre information to

your mobile phone

Wiehl, 15.11.2019 --- Greater safety and economy is hard to come by in the transport industry. Or is it? BPW is now delivering the AirSave tyre pressure control system that pays for itself in the first year: The system achieves enormous savings in terms of fuel, tyres and time, as well as keeping your stress levels down. This is confirmed by the forwarders involved in the practical tests.

There is a close correlation between tyre and cost pressure: even minimal pressure differences caused by constantly changing temperatures, load and road conditions increase fuel consumption and tyre wear. How an intelligent tyre pressure control system saves costs was tested by BPW in practice with transport companies: "The purchase pays for itself astonishingly quickly", confirms Alfred Weyres, owner and managing director of Alfred Weyres Spedition GmbH. "The system ensures a permanently optimised roll resistance; fuel economy is clear – and added is the considerably longer tyre mileage. Because the fabric carcass is conserved, the system also optimises retreadability."

Save about a thousand euros per year in fuel and tyre wear

For a three-axle vehicle with a mileage of 120,000 kilometres per year and an average pressure deviation of 10 per cent, AirSave delivers a cost benefit of 700 euros per year – solely as a result of the fuel savings (around 250 litres) and the longer service life of the tyres. At 200,000 kilometres, the cost savings increase to almost 1,000 euros. And they do so year after year. "The gains in time and safety have not yet been factored into this calculation," emphasises Caren Freudenberg, Product Manager at BPW in Wiehl. "The driver no longer has to constantly check and readjust the tyre pressure on the trailer one at a time. AirSave thus also reduces the risk of tyre bursts, which can lead to considerable downtimes or even serious accidents." If the tyre pressure drops rapidly because of damage, AirSave alerts the driver and allows an immediate planned stop in the workshop. The telematics network is already prepared in the factory by BPW. This way, it is not only the driver who is always informed about the tyre pressure via the smartphone app. The authorised agent can also be informed automatically just in case.

That's why AirSave is not only a benefit for the transport company, but for road safety as well – and for the environment: the system cuts CO2 emissions and litter from burst tyres remnants.

Alfred Weyres was already completely convinced by the test drives with the AirSave system: "We've received excellent feedback from our drivers, technicians and dispatchers. AirSave not only saves costs and time, but reduces your stress as well. When there's no need to worry about the tyres, driving and planning is simply more relaxed. We will consistently order our trailers with AirSave in the future."

"The first tyre pressure control system with BPW quality"

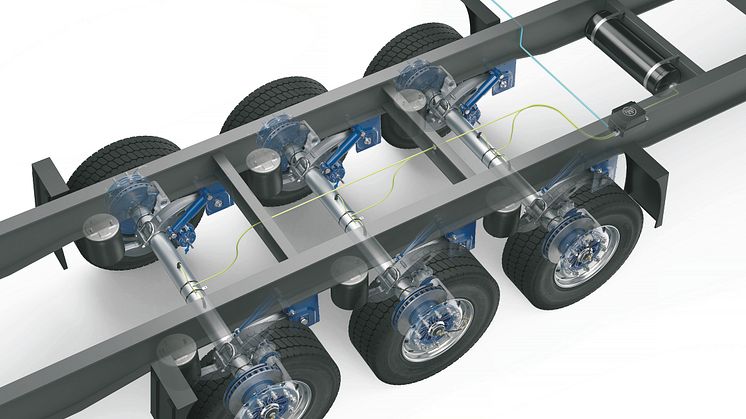

The engineers at BPW haven't reinvented the wheel with AirSave, just incorporated the market- leading P.S.I. system from Celerity DRS and developed it further with numerous measures. BPW thus places great importance on an independent, particularly robust and easy to install design for all external components mounted on the wheel end. The system uses the existing trailer pneumatics and, with a fully automatic booster pump, ensures that the preset tyre pressure is maintained at all times. The air is guided through the axle beam to the wheel end and from there to the tyre valve. The system will uncover a consistent loss of pressure. AirSave kicks in at a pressure deviation of just 0.2 bar – making it more reliable than other tyre pressure monitoring systems. AirSave is maintenance-free for three years. Starting in November, BPW will supply all 9-12 t ECO Plus axles intended for AirSave with the corresponding pre-assembled components. Product Manager Freudenberg: "AirSave is the first tyre pressure control system that meets our requirements in terms of sealing and sturdiness."

As is typical for BPW products, the system can be connected digitally. An optional connection to the "cargofleet3" telematics portal from idem telematics is fitted by the manufacturer. The driver can keep an eye on the condition of all tyres at all times via the corresponding smartphone app. The app also indicates whether air has been readjusted.

Vehicle operators can order the AirSave system ex works directly from their preferred vehicle manufacturer. André Gerken of Celerity DRS is delighted about the collaboration with BPW: "Together with BPW's engineers, we have extensively developed important components. By doing so, we are together lifting the P.S.I. system to an unprecedented level of quality. We are delighted that BPW has decided to partner with Celerity CRS, and we are convinced that our joint solution will quickly establish itself in the market."

BPW AirSave on YouTube: BPW’s AirSave allows you to continuously track and control your tyre pressure while driving. For maximum cost-effectiveness and greater safety thanks to optimal tyre pressure.

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen Kommanditgesellschaft is the parent company of the BPW Group. With over 1,600 employees, including around 120 trainees, the family-owned company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also offers vehicle manufacturers and operators the ability to increase the efficiency of their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en