Press release -

Climate and cost-efficient trailers are now instantly recognisable: BPW AirSave wins the European Transport Prize for Sustainability

- Tyre pressure control components on the wheel set efficient trailers apart

- Saves fuel, CO2, time and sustainably protects against dangerous tyre blowouts

- Cost savings of up to 1,000 euros - break even after just one year

- AirSave complies with new EU regulations for tyre pressure monitoring

- Vehicle manufacturer SEKA-NUTZFAHRZEUGE are "delighted with the quality and ease of installation"

Wiehl, 27/11/2019 --- All truck drawbar trailers look the same to the average consumer. But now even the layman can identify which trailer is safe, climate-friendly and cost-saving, as with just a glance at the wheel hubs you can immediately recognise whether the BPW AirSave system has been installed. It has now been awarded the highest European sustainability award in the transport industry. And it's not only forwarders who are enthusiastic.

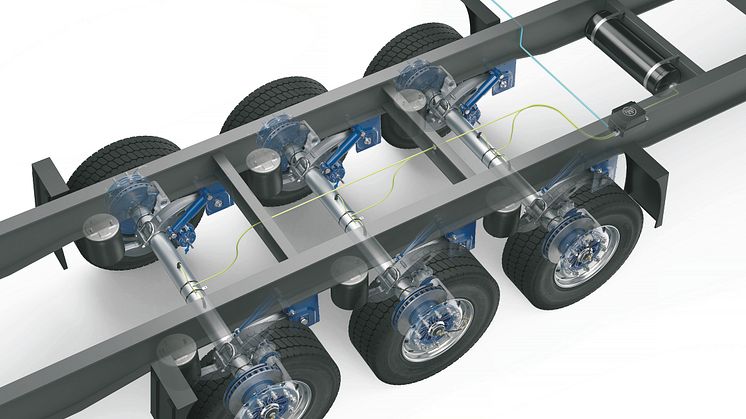

The air pressure of the truck tyre has a decisive influence on the safety and efficiency of transport. This is why EU member states in Brussels recently ruled that tyre pressure monitors will be legally required from 2022 onwards. The judges for the highest European Transport Prize for sustainability therefore were apt in their timing when it awarded BPW in Munich for the new active tyre pressure control system AirSave just a few days after the ruling. BPW is already significantly ahead of the EU and not only monitors tyre pressure, but also keeps tyre pressure permanently in the optimum range completely automatically. The system can be recognised with just at a glance at the wheels, where a pressure line leads from the centre of the hub into the tyre valve. The tube is only the externally visible side of a system that pumps air from the air tank through the axle and wheel end into the tyre, thus regulating the air pressure. The cost advantage is clear: up to 700 euros and 655 kilos of CO2 per year just through fuel and tyre savings based on a 3-axle trailer (calculated on a typical mileage of 120,000 km/year and an average pressure deviation of 10%). With a mileage of 200,000 kilometres, a saving of up to 1,000 euros is possible. This does not include the reduced accident and downtime risks, time savings for drivers or the debris from burst tyres that is no longer dangerously scattered across motorways.

BPW has developed and tested AirSave in close cooperation with forwarders and even vehicle manufacturers have expressed their enthusiasm. Dragan Stanojlovic, Managing Director of SEKA-NUTZFAHRZEUGE GmbH & Co KG said "Our employees are delighted with the installation of the BPW AirSave system. BPW has intelligently thought through the assembly process and has set it up perfectly with pre-assembled components. This means the AirSave installation can be integrated smoothly and efficiently into our processes. All you have to do is replace the wheel hub caps, install the rotor and you're done. In addition, the new system looks very good and high-quality. We recommend it highly to our customers". The digital networking capability is typical for BPW: as the first system of its kind, AirSave communicates directly with the telematics system, the driver's smartphone and, if required, also with the dispatcher.

Ralf Merkelbach, Head of Key Account Management for Large Fleets Europe at BPW, accepted the European Transport Prize for Sustainability (ETPN) in Munich on behalf of the BPW Group: "BPW is committed to establishing active tyre pressure control as a standard in the transport and trailer industry. For us, the reliability and outstanding economy of the system are the key to broad market acceptance. The European Transport Prize for Sustainability is an important endorsement for us, for which we are very grateful. It proves that the benefits of our system are recognised by the industry's leading professionals and institutions."

The independent expert jury of the EPTN includes well-known personalities from business, science, associations and the media with profound knowledge of the commercial vehicle industry: Prof. Dr. Dirk Engelhardt, Chairman of the Board of the Bundesverband Güterkraftverkehr Logistik und Entsorgung (BGL) e.V., Guido Zielke, Head of the Road Transport Department at the Federal Ministry of Transport and Digital Infrastructure (BMVI), Prof. Dr. Ing.Uwe Clausen, Head of the Fraunhofer Institute for Material Flow and Logistics, Markus Otremba, Head of Load Securing Section, TÜV SÜD Auto Service GmbH, Axel Salzmann, Lawyer, Head of KRAVAG-LOGISTIC Versicherungs-AG's Competence Centre for Road Transport and Logistics, and Torsten Buchholz, Editor-in-Chief of the Transport newspaper and Robert Domina, Editor and Head of Testing and Technology at Huss-Verlag's Transport newspaper.

**************************************************************************************

BEHIND THE SCENES - AN INSIGHT INTO DEVELOPMENT AT BPW

BPW uses personal networks in the transport and logistics industry to bring new ideas to the market: In the current Annual report of the BPW Group, you can read who is involved in the development of BPW innovations with the "iGurt" as an example.

**************************************************************************************

Related links

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen Kommanditgesellschaft is the parent company of the BPW Group. With over 1,600 employees, including around 120 trainees, the family-owned company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also offers vehicle manufacturers and operators the ability to increase the efficiency of their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 7,200 staff in more than 50 countries and achieved consolidated sales of 1.48 billion euros in 2017. www.bpw.de/en