Press release -

European Commission makes tyre pressure monitoring for trailers compulsory from mid 2022

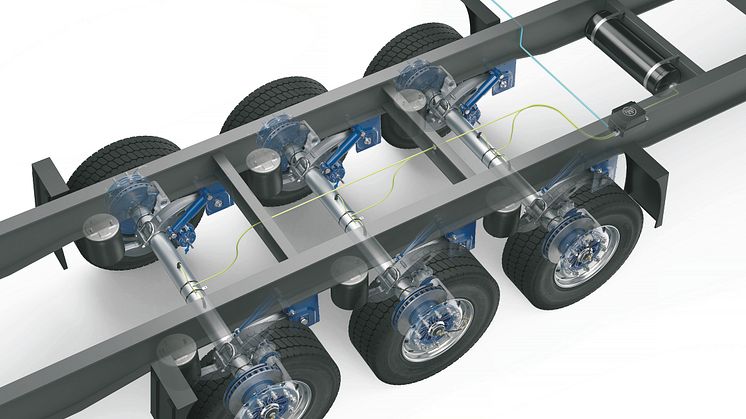

- Existing BPW AirSave tyre pressure control system already exceeds forthcoming EU requirements

- More fleet uptime: system helps avoid accidents, extends tyre lifespan and reduces CO2 and diesel consumption dramatically

- Potential savings of around 1,000 euros per vehicle per year

- Caren Freudenberg: ‘Higher diesel prices are driving demand for AirSave’

Wiehl, 11.4.2022 --- There are many good reasons to opt for a tyre pressure control system like AirSave from BPW: it saves tyres, fuel and nerves – and already pays off within its first year. Now there’s another good reason to order all trailer running gears with a tyre pressure monitoring system (TPMS) or AirSave from BPW: the European Commission is making tyre pressure monitoring compulsory from mid 2022.

Tyre pressure monitoring systems have long been legally required in many vehicle categories: they first made their way into legislation in the US in 2008, followed shortly thereafter by Japan, South Korea, and, in 2012, the EU. An amendment to the UN ECE R 141 Regulation is planned for 2022 that will also require a tyre pressure monitoring system for trailers for the first time. The legislation will be implemented in two parts: from July 2022, it shall apply to all new vehicle type approvals; from July 2024, tyre pressure monitoring will be required for all newly registered trailers. The UN ECE is a regulatory framework of the United Nations Economic Commission for Europe; it also applies far beyond the borders of the EU. Parties to the agreement include countries such as the UK, Russia, Turkey, all Eastern European nations, South Africa, Australia and many more.

UN ECE R 141 precisely stipulates the tyre pressure monitoring system’s range of functions. When a loss of pressure greater than 20 per cent or a system malfunction occurs, the driver must receive a warning within ten minutes. In tyre pressure refill systems, a change in pressure of five per cent must be automatically offset again within ten minutes. A warning must be displayed in the driver cab; the systems’ sensor data can be transmitted by cable or wirelessly. ‘Detecting a loss of pressure on the move is good – but regulating it automatically is even better,’ says Caren Freudenberg, product manager at BPW in Wiehl. ‘That offers added uptime that truly pays off. We therefore recommend that all vehicle operators now order their trailers with the AirSave tyre pressure control system.’

For Caren Freudenberg, however, using a tyre pressure control system in the trailer isn’t just a matter of meeting requirements – it’s about good business sense: ‘skyrocketing fuel prices have seen a marked increase in demand for our AirSave system’. For a three-axle vehicle with a mileage of 120,000 kilometres per year and an average pressure deviation of ten per cent, AirSave delivers a cost benefit of 700 euros per year – solely as a result of the fuel savings (around 250 litres) and the longer service life of the tyres. At 200,000 kilometres of mileage, the cost savings increase to almost 1,000 euros. And they do so year after year. ‘The gains in time and safety have not yet been factored into this calculation,’ emphasises Caren Freudenberg.

Caren Freudenberg, product manager at BPW: "Skyrocketing fuel prices have seen a marked increase in demand for our AirSave system"

Mustafa Celik, CEO of M. Celik Transport GmbH, based in Iserlohn, North Rhine-Westphalia, has already had his new order of 15 semi-trailers for 2022 kitted out with the AirSave system. The haulier has specialised in demanding coil transport for years. Its constantly growing fleet currently numbers around 60 vehicles and 75 semi-trailers. The fleet has already been connected with the system from idem telematics since 2016. This allows data from the tyre pressure monitoring system to be transmitted to drivers, planners and other predefined recipients in real time. ‘We’ve already been able to bring the vehicle safely to its destination despite an incipient tyre issue on two occasions, as the system continually re-adjusted the system’s air pressure,’ says Mustafa Celik on motionist.com. Without AirSave, there would have been a risk of unplanned vehicle downtime and an expensive tyre change on the move.

Related links

Topics

Categories

About BPW Bergische Achsen Kommanditgesellschaft

BPW Bergische Achsen KG is the parent company of the BPW Group. With around 1,500 employees, including around 100 trainees, the family-run company has been developing and producing complete running gear systems for truck trailers and semi-trailers at its headquarters in Wiehl since 1898. BPW’s technologies include axle systems, brake technology, suspension and bearings. BPW’s trailer axles and running gear systems are in use in millions of vehicles around the world. An extensive range of services also provides vehicle manufacturers and vehicle operators with the opportunity to increase economic efficiency in their production and transport processes. www.bpw.de/en

About the BPW Group

The BPW Group researches, develops and manufactures everything needed to ensure that transport keeps moving and is safe, illuminated, intelligent and digitally connected. With its brands BPW, Ermax, HBN, HESTAL and idem telematics, the company group is a preferred system partner of the commercial vehicle industry around the globe for running gear, brakes, lighting, fasteners and superstructure technology, telematics and other key components for trucks, trailers and buses. The BPW Group offers comprehensive mobility services for transport businesses, ranging from a global service network to spare parts supply and intelligent networking of vehicles, drivers and freight. The owner-operated company group currently employs 6,800 staff in more than 50 countries and achieved consolidated sales of 1.372 billion euros in 2020. www.bpw.de/en